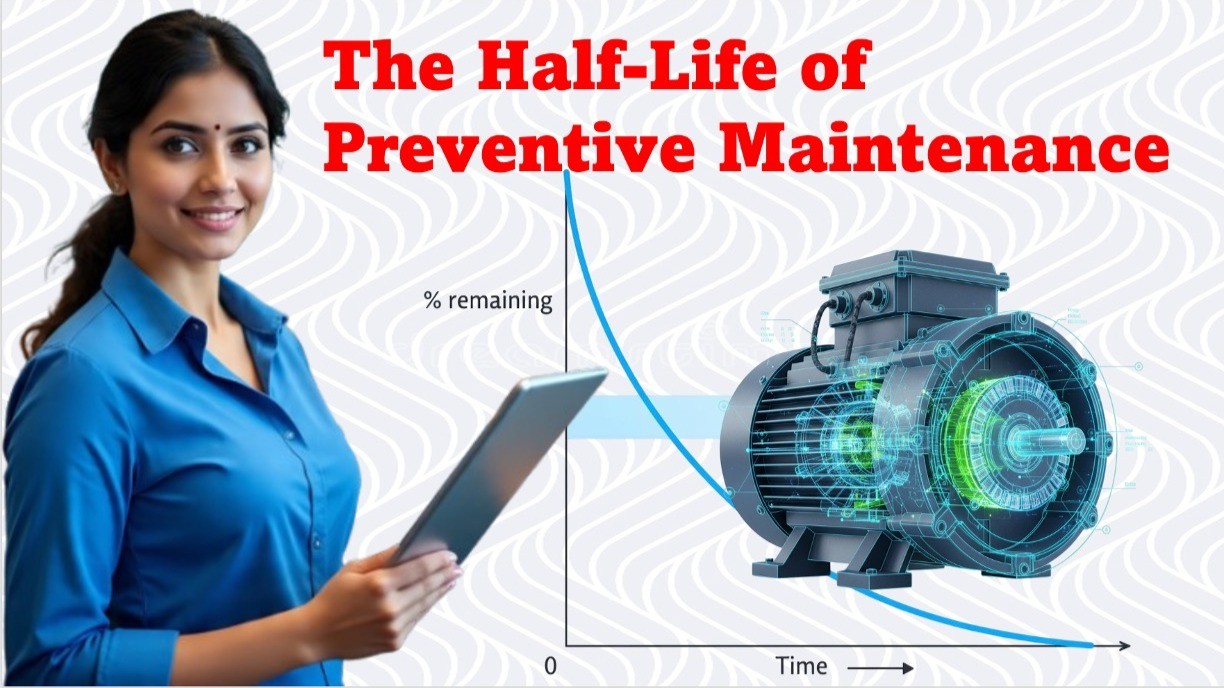

The Half-Life of Preventive Maintenance

Why Preventive Maintenance Tasks Lose Effectiveness Over Time—and How Organizations Fail to Notice

Preventive Maintenance (PM) is one of the most deeply trusted concepts in industrial operations. It represents discipline, foresight, and engineering intent. Once a PM task is defined, approved, and embedded into a CMMS, it often becomes institutionalized—repeated monthly, quarterly, or annually with little scrutiny.

Yet across industries—manufacturing, power generation, oil & gas, chemicals, utilities—organizations face the same paradox:

PM compliance improves, maintenance effort increases, yet reliability declines.

This contradiction is not accidental. It is the result of a phenomenon that remains largely unexplored in mainstream maintenance thinking:

Preventive maintenance has a half-life.

Like physical systems, PM tasks degrade in effectiveness over time. They do not fail abruptly. They fade—quietly, gradually, and invisibly—until they no longer protect the asset they were designed to safeguard.

This article explores the concept of the half-life of preventive maintenance, why it exists, how it manifests, why organizations fail to detect it, and how maintenance leaders can reverse its effects.

Understanding the Half-Life of Preventive Maintenance in Industrial Reliability

The half-life of preventive maintenance refers to the point at which a PM task delivers only a fraction of its original failure-prevention or risk-reduction value, even though it continues to be executed exactly as written.

The task still exists in the CMMS.

The work order still closes on time.

Compliance metrics still look excellent.

But the protective value—the reason the PM was created in the first place—has eroded.

This concept challenges one of the most dangerous assumptions in maintenance management:

Once a PM works, it will always work.

In reality, PM effectiveness is not permanent. It is conditional, contextual, and time-bound.

Why Preventive Maintenance Tasks Inevitably Lose Effectiveness Over Time

Asset Operating Conditions Change While PM Logic Remains Static

Industrial assets evolve throughout their lifecycle. Load profiles shift. Production demands increase. Feedstock quality changes. Control strategies are modified. Environmental exposure intensifies. Equipment that once operated in steady-state may now cycle aggressively.

Preventive maintenance tasks, however, are often written once—during commissioning or early reliability studies—and then left unchanged for years or even decades.

This creates misalignment. A lubrication interval optimized for moderate load becomes harmful under continuous high stress. An inspection frequency based on clean service becomes inadequate in corrosive environments.

The PM still executes—but no longer addresses the dominant failure mechanisms.

Failure Modes Evolve Across the Asset Lifecycle

Failure modes are not static. Early-life failures differ fundamentally from mid-life degradation and late-life wear-out mechanisms. Aging assets experience corrosion, fatigue, erosion, creep, insulation breakdown, and cumulative damage that did not exist during early operation.

Yet PM programs often treat failure modes as permanent truths.

When maintenance strategies fail to adapt to asset aging, PM tasks remain focused on obsolete risks while emerging failure modes go undetected. Over time, the maintenance program becomes historically accurate—but operationally irrelevant.

Human Execution Drift Reduces PM Effectiveness

Even the best PM tasks are executed by humans, and human behavior adapts to experience.

When inspections repeatedly find no issues, technicians subconsciously reduce rigor. Measurements become estimates. Visual checks become quicker. Steps perceived as unnecessary are skipped. Pass/fail criteria become subjective.

This is not negligence. It is human optimization in response to perceived low value.

The PM task still closes successfully, but its detection capability steadily declines. Since most organizations measure completion—not quality—this decay remains invisible.

Obsolete Tools, Standards, and Techniques Undermine Preventive Maintenance

Many PM tasks are based on standards, tolerances, and inspection methods that were valid when written. Over time, industry standards evolve, equipment design improves, and failure detection techniques advance.

A PM that once represented best practice can quietly fall below modern expectations for safety, reliability, or risk control.

The task is still performed correctly—according to outdated logic.

Over-Maintenance Accelerates the Decline

As PM effectiveness decreases, organizations often respond by adding more PMs or increasing frequencies. This creates the illusion of control but often introduces new risks.

Intrusive maintenance increases the likelihood of maintenance-induced failures: disturbed bearings, damaged seals, misalignment, incorrect reassembly, contamination, and human error.

Ironically, doing more preventive maintenance can accelerate asset degradation when PM logic is already past its half-life.

Why PM Half-Life Remains Invisible in Maintenance Management

PM Compliance Metrics Create False Confidence

Most maintenance KPIs focus on activity: schedule compliance, backlog size, overdue work orders. These metrics measure discipline—not effectiveness.

A PM can be completed 100% on time while delivering zero risk reduction. Dashboards turn green, leadership relaxes, and no one questions whether the work still matters.

Failure Investigations Rarely Question Maintenance Strategy

When failures occur, investigations focus on immediate technical causes: broken components, material defects, operating upsets. Rarely does the analysis ask whether the preventive maintenance strategy itself was outdated.

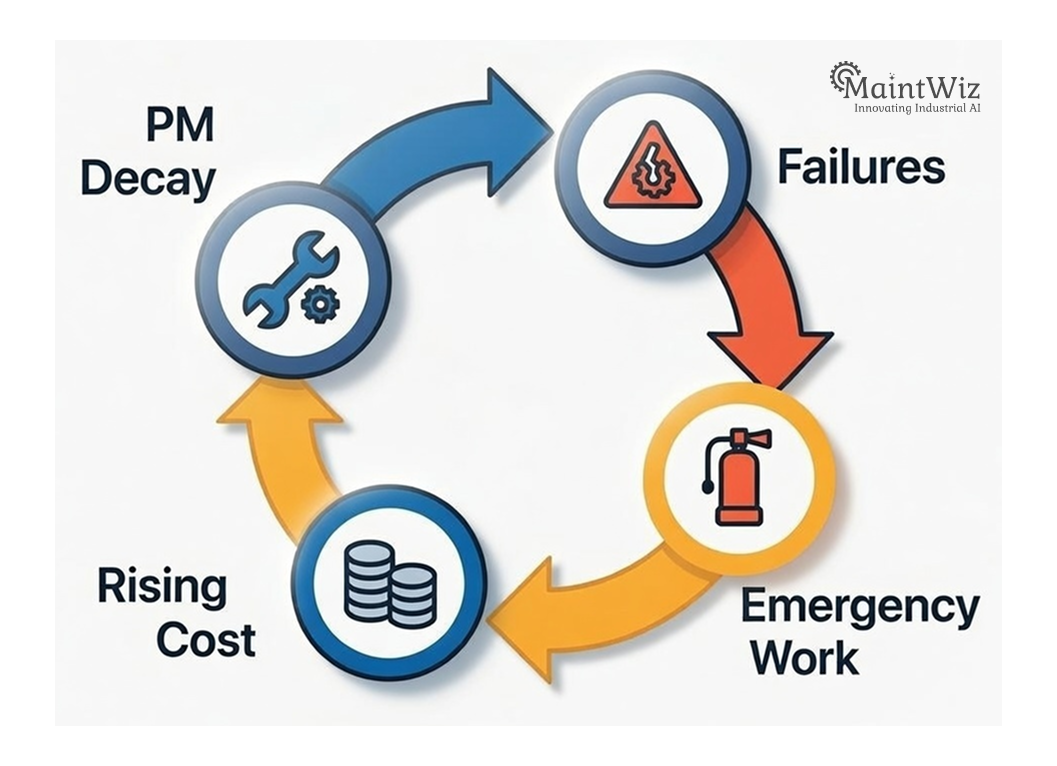

As a result, PM half-life is almost never identified as a root cause. The same tasks are repeated, and the same failures return.

Maintenance Success Is Defined as Activity, Not Protection

Many organizations unconsciously equate busy maintenance teams with effective maintenance. Work volume becomes a proxy for value.

This mindset masks PM decay. The organization feels productive—even as assets become increasingly vulnerable.

The Operational Consequences of Expired Preventive Maintenance

Rising Corrective Maintenance Despite Heavy PM Effort

One of the clearest symptoms of PM half-life is increasing corrective maintenance in plants with strong PM compliance. Failures occur despite intensive preventive activity, creating frustration and confusion.

Emergency Work Becomes Normalized

As PM effectiveness declines, unplanned work increases. Emergency repairs become routine. Firefighting replaces planning. This further degrades PM execution quality, accelerating the cycle.

Technician Fatigue and Loss of Trust in PM Programs

When PMs repeatedly fail to prevent breakdowns, technicians lose faith in the system. Tasks are seen as bureaucracy rather than protection. Engagement declines, and execution quality drops further.

Identifying Preventive Maintenance Tasks Past Their Half-Life

Failures Occurring Soon After PM Execution

When assets fail shortly after preventive work, it often indicates that the PM either failed to detect degradation or actively introduced risk. This pattern is a strong indicator of expired PM logic.

PM Tasks That Never Detect Degradation

A PM that never finds issues may appear successful, but over time it loses credibility and rigor. If a task consistently produces no findings, it may no longer be aligned with real failure mechanisms.

Increasing PM Hours Without Reliability Improvement

When PM workload grows while Mean Time Between Failures (MTBF) stagnates or declines, effectiveness has likely decayed. The organization is investing more effort for diminishing returns.

Preventive Maintenance Instructions That Haven’t Been Reviewed in Years

PMs older than five to seven years without technical review are high-risk candidates for half-life decay. Time alone erodes relevance.

Restoring Preventive Maintenance Effectiveness Through Strategy Renewal

Treat Preventive Maintenance as a Living Risk Control

Every PM task should be explicitly linked to a specific failure mode and a clear prevention or detection mechanism. If that link cannot be articulated, the task should be challenged.

Preventive maintenance must evolve alongside the asset it protects.

Implement Preventive Maintenance Effectiveness Reviews

Organizations should periodically evaluate PMs based on outcomes, not completion. Did the task detect degradation? Did it prevent failure? Is it still the least intrusive and most cost-effective control?

These reviews require disciplined thinking—not complex software.

Transition from Time-Based PM to Condition-Based Logic Where Appropriate

Condition-based maintenance can extend PM effectiveness when grounded in failure physics. However, technology should not replace understanding. Sensors without strategy simply shift the problem.

Create Structured Feedback Loops from Technicians

Technicians often know which PMs no longer make sense. Capturing this insight systematically transforms tacit knowledge into strategy renewal. Ignoring it guarantees PM decay.

Measure Preventive Maintenance Value, Not Volume

Leading organizations evaluate PMs based on risk reduction per labor hour, intrusiveness, and failure prevention effectiveness. This reframes PM as a strategic investment rather than a checklist obligation.

The Role of Reliability Engineering in Managing PM Half-Life

Reliability engineering provides the tools to combat PM decay: Failure Modes and Effects Analysis (FMEA), Reliability-Centered Maintenance (RCM), Weibull analysis, and risk-based maintenance modeling.

However, these tools must be applied continuously—not as one-time exercises. Reliability is not designed once; it is maintained.

The Cultural Barrier: Why Organizations Resist Challenging PMs

Questioning PMs feels risky. Removing tasks feels irresponsible. Compliance is safe; change is not.

Yet the greatest reliability risks often lie in unquestioned routines. Mature maintenance cultures encourage intelligent challenge, evidence-based decisions, and continuous renewal of strategy.

The Future of Preventive Maintenance in Asset Management

The next evolution of maintenance excellence will not be driven solely by digital tools, AI, or predictive analytics. Those technologies amplify good strategy—but cannot compensate for outdated logic.

The real competitive advantage lies in organizations that learn to maintain their maintenance systems with the same rigor applied to physical assets.

Final Reflection: Preventive Maintenance Does Not Fail—It Expires

Preventive maintenance rarely fails dramatically. It fades quietly.

It fades as assets change.

It fades as people adapt.

It fades as failure modes evolve.

And by the time failures expose the truth, the cost has already been paid.

Every PM task has a half-life.

Every maintenance strategy expires.

The only question is whether your organization recognizes this before the next failure does.

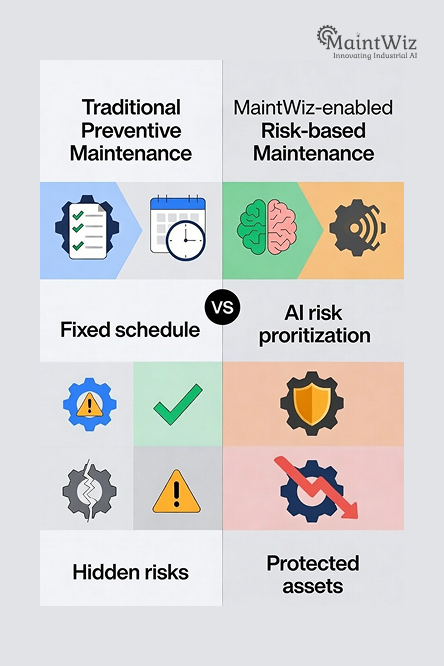

How MaintWiz AI CMMS can redefine your Preventive Maintenance

Preventive maintenance fails not because teams don’t execute—but because PM logic ages silently. Most CMMS platforms track completion, not protection. MaintWiz CMMS is designed to expose, challenge, and continuously renew preventive maintenance before it loses effectiveness. It turns maintenance from a static checklist into a living, risk-driven system.

- PM Effectiveness Analytics — Beyond Green Dashboards

MaintWiz connects PMs to failures, downtime, and repeat defects, revealing which tasks still prevent breakdowns—and which have outlived their value.

- Built-In PM Review Cycles

PMs in MaintWiz are periodically flagged for relevance review, preventing outdated tasks from surviving unchecked for years.

- Failure-Mode–Linked Maintenance

Every PM can be mapped to specific failure modes, keeping maintenance logic aligned with real degradation mechanisms.

- Technician Insight Capture at Execution

MaintWiz converts technician observations into structured feedback, ensuring frontline intelligence continuously improves PM strategy.

- Maintenance-Induced Failure Detection

By analyzing post-PM failures, MaintWiz identifies tasks that unintentionally increase risk—stopping harmful maintenance early.

- Asset Aging Awareness

PM strategies evolve automatically as assets age, preventing early-life maintenance logic from being applied to end-of-life equipment.

- PM Intrusiveness Tracking

MaintWiz highlights overly intrusive PMs, helping teams balance inspection depth with failure risk.

- Repeat Failure Pattern Recognition

Recurring breakdowns trigger strategy reviews, not just work orders—addressing root causes at the maintenance-logic level.

- PM Rationalization Without Guesswork

Data-backed insights allow safe elimination or consolidation of low-value PMs.

- Risk-Based Maintenance Prioritization

Maintenance effort is redirected toward high-risk assets instead of evenly distributed across all equipment.

- Continuous Strategy Renewal

MaintWiz treats maintenance strategy as a living system—constantly learning, adapting, and improving.

Call to Action

If your PMs are executed perfectly but failures persist, the issue isn’t discipline—it’s decay.

MaintWiz CMMS helps you detect PM half-life before it costs you reliability, safety, and credibility.

Company