Checklists in the Age of AI: Transforming Maintenance with Smart Tools

In the modern industrial landscape—where complexity, downtime costs, and digital expectations are soaring—maintenance teams can no longer rely on paper, tribal knowledge, and reactive checklists. With the advent of AI-driven CMMS software, checklists are evolving from static lists of tasks into strategic engines that drive reliability, asset intelligence, and operational excellence.

Today’s maintenance leaders demand tools that anticipate issues, guide actions, and improve over time—not just document what has already failed. This article dives deep into how AI changes maintenance checklists, why that matters, and how MaintWiz CMMS fits into this future.

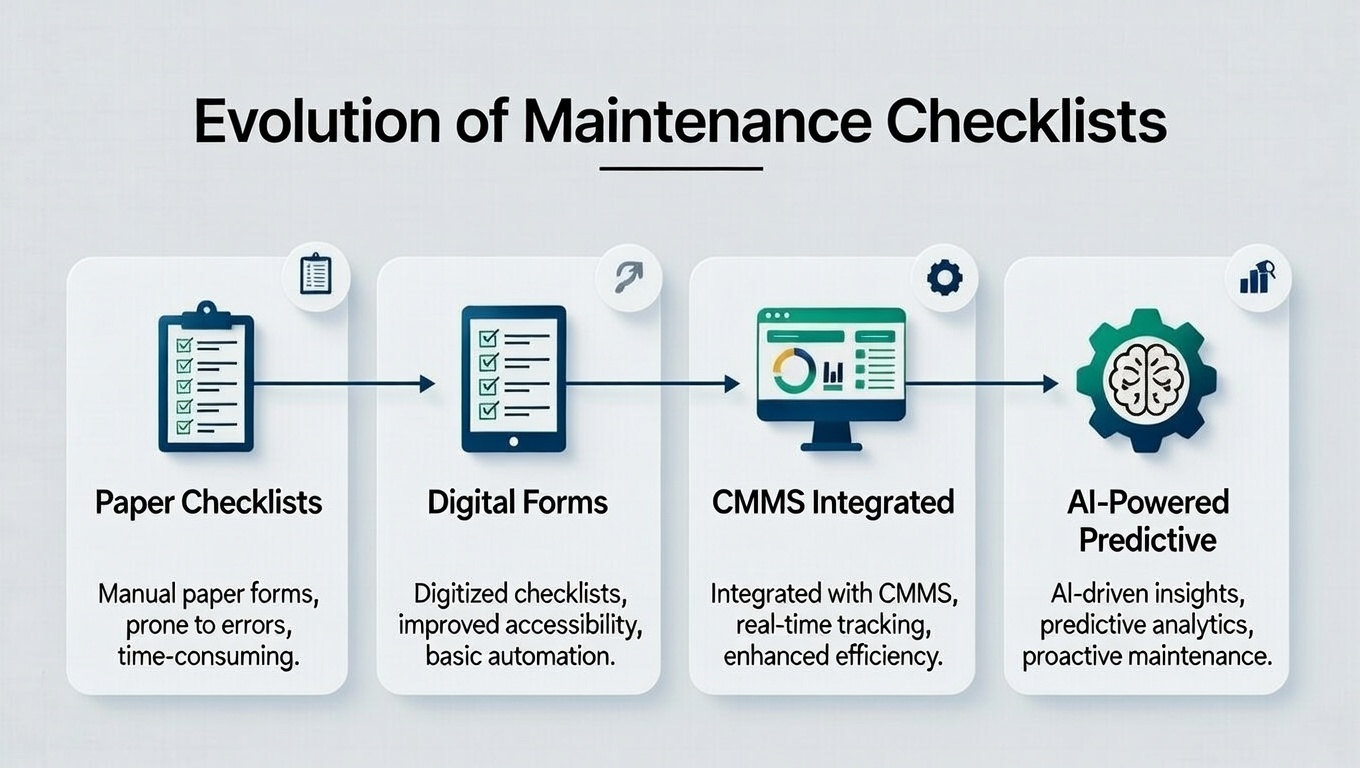

The Evolution of Maintenance Checklists: From Paper to Predictive

Understanding the Maintenance Checklist Revolution

Industrial checklists were once simple: inspect, record, and sign. While this approach worked at small scales, it fails in complex, high-speed environments with thousands of assets, multimillion-dollar consequences for downtime, and regulatory scrutiny across ISO, OSHA, and FDA standards.

AI has changed the equation.

Why checklists alone aren’t enough today:

- Static Tasks Don’t Respond to Context – Traditional checklists lack awareness of asset history or real-time performance.

- Human Error Risk is High – Manual checklists depend on consistent discipline, which varies by site and individual.

- Lack of Integrated Insights – When checklists are separate from the maintenance system, they don’t influence schedules, BOMs, or KPIs.

AI-powered tools transform checklists into intelligent sequences that adapt, predict, and learn.

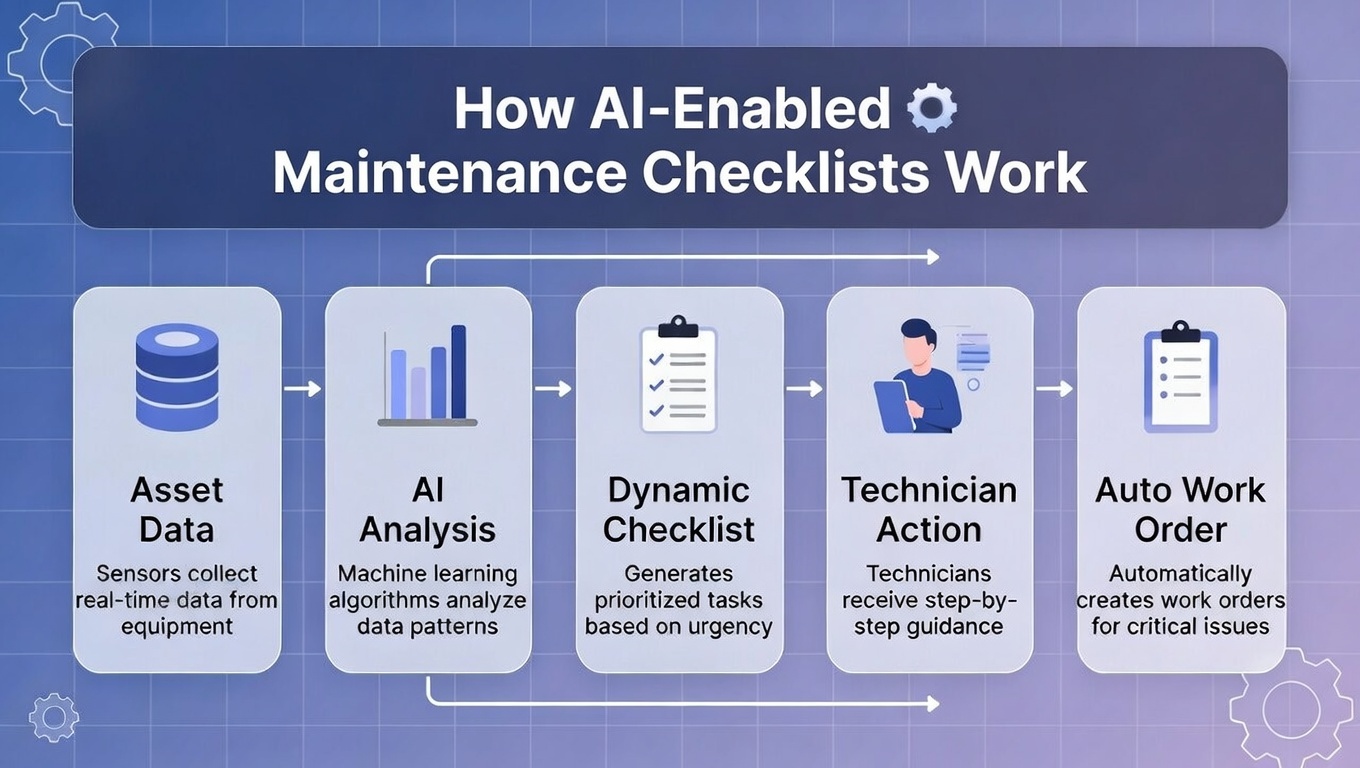

What AI-Enabled Checklists Do Differently

- Contextual Task Prioritization

Smart Task Ordering: AI analyzes work histories, failure patterns, and real-time sensor data to determine which checks matter most—rather than presenting a generic list.

Why It Matters: Teams focus first on high-risk assets, reducing unplanned breakdowns.

- Predictive Guidance

Root Cause Hints: Based on past faults and patterns, AI can suggest what to look for before a technician even opens a checklist.

Impact: Faster detection of early failure signs and more consistent problem diagnosis.

- Dynamic Checklist Adaptation

Condition-Driven Tasks: If sensors report abnormal vibration or heat, the AI expands the checklist with relevant questions and measurements.

Outcome: More intelligent, condition-aware instructions that save valuable hours.

- Seamless Work Order Integration

Automatic Work Triggers: When AI detects anomalies via checklist inputs, it can automatically create prioritized work orders.

Benefit: Faster response time and fewer overlooked issues.

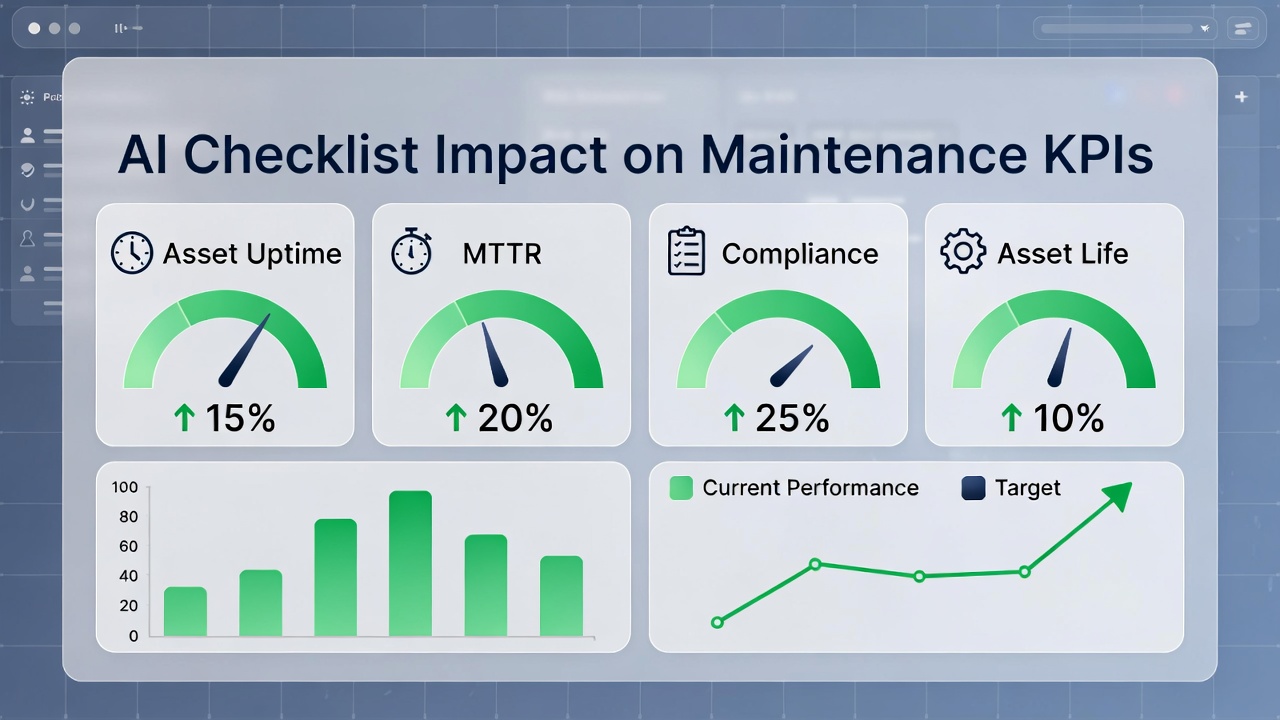

Why AI-Driven Maintenance Checklists Matter for Plant Performance

Maintenance checklists aren’t just lists—they are the backbone of operational reliability. When enhanced with AI, they become fundamental drivers of key Industrial KPIs:

Increase in Asset Uptime

Predictive checklists that trigger maintenance before failure dramatically reduce unplanned downtime.

Lower Mean Time to Repair (MTTR)

By guiding technicians with context-aware instructions, issues are resolved more efficiently.

Improved Asset Lifespan

Routine checks informed by real performance data extend useful life through timely repairs and adjustments.

Better Compliance and Audit Readiness

Automated, AI-verified checklists ensure that regulatory requirements are met and documented consistently.

Anatomy of a High-Performance AI Checklist

To implement next-generation checklists, you need more than paper or PDFs—you need integration into a CMMS like MaintWiz that ties checklist data directly into maintenance intelligence.

Components of an AI-Power Checklist

- Real-Time Asset Condition Inputs

Gather IoT or sensor data directly from assets and use it to tailor checklist steps. - Historical Failure Integration

Use past data to determine which tasks should appear or be emphasized. - Trigger-Based Workflow Activation

When thresholds are crossed, tasks trigger work orders and escalation processes.

Mobile Accessibility

Technicians need context-rich digital checklists accessible anytime, anywhere.

How Maintenance Teams Use AI Checklists in Practice

Here are real examples of how AI powered checklists change maintenance work:

Predictive Inspection

Technicians receive a checklist that changes based on real-time asset data and predictive analytics, reducing reactive failures.

Compliance Automation

Checklists can enforce safety and audit requirements, with automated logs and timestamps for regulatory proof.

On-Demand Technician Guidance

Field technicians get step-by-step, context-sensitive instructions that reduce guesswork and improve task accuracy.

Maximizing ROI with AI Checklists and CMMS

Maintenance investments must pay off—so the shift to AI readiness should focus on concrete returns:

Operational Efficiency

AI checklist automation reduces admin time, resurfaces critical data, and limits repeat inspections.

Resource Optimization

Technicians perform the right next task with priority sequencing that drives throughput.

Improved Decision Support

AI adds insights like risk likelihood, failure prediction, and optimization opportunities—helping supervisors make smarter choices.

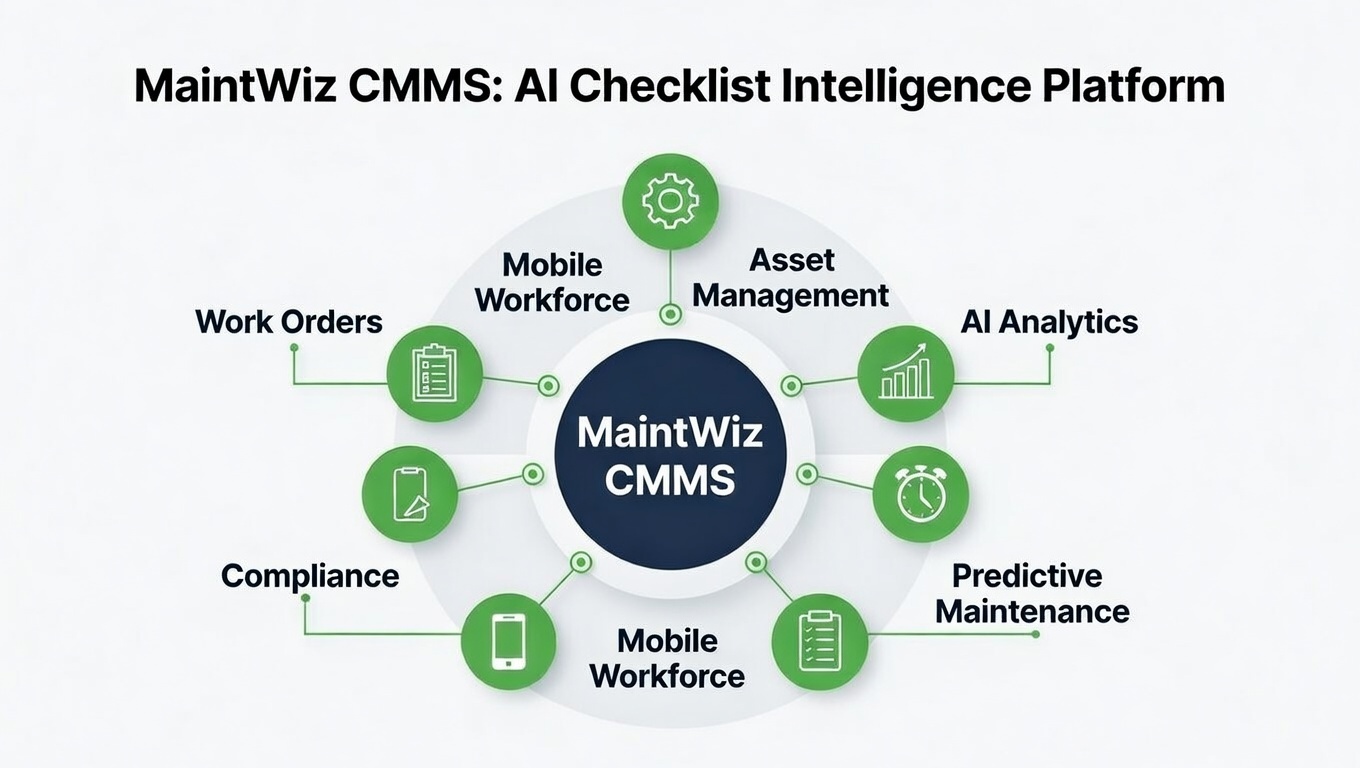

Why AI Checklists and CMMS Integration Is the Future of Maintenance

Checks and balances are critical in any maintenance regime. But when those checks reside in disconnected systems or siloed spreadsheets, the insights they generate are lost. AI and connected maintenance platforms like MaintWiz CMMS bring these elements together in a powerful, unified system that drives real results:

- Asset Management Optimized with AI Insights – MaintWiz enables complete lifecycle tracking and asset intelligence to support smarter maintenance decisions.

- Predictive Maintenance Built on Checklist Data – AI mechanisms generate predictive work orders based on live data and checklist results.

- Seamless ERP and IoT Integration – These systems ensure intelligent checklists pull from and feed into real-time operational streams.

Mobile Accessibility for Field Technicians – Technicians use mobile devices to execute checklists and instantly sync data.

Real World AI Checklist Benefits You Can Demonstrate

Maintenance teams implementing AI checklists alongside MaintWiz CMMS report measurable improvements:

Reduced Unplanned Downtime: Intelligently prioritizing inspections prevents failures.

Higher Asset Availability: Real-time checklist data drives proactive maintenance schedules.

Faster Response Time: Automated triggers and mobile execution speed repairs.

Better Compliance & Documentation: Digital logs ensure audit readiness.

Why MaintWiz CMMS Is the Ideal Platform for AI-Powered Maintenance Checklists

In the context of checklist modernization, MaintWiz CMMS doesn’t just support checklists—it transforms them into AI-driven reliability workflows:

- Unified Asset Management System

MaintWiz CMMS brings complete asset lifecycle visibility, enabling checklists to evolve with asset performance realities.

- Predictive Analytics Engine

AI insights push relevant tasks into checklists based on real-time data trends and safety thresholds.

- Seamless Mobile Accessibility

Field teams can access, execute, and update checklists on mobile devices, keeping data live and accurate.

- Integrated Compliance and Safety Features

Checklists are automatically tied to industry standards and audit requirements.

- Intelligent Work Order Automation

When checklist checks indicate action is needed, MaintWiz auto-generates prioritized work orders.

Conclusion: AI Checklists Aren’t Optional — They’re Competitive

Maintenance leaders in 2026 and beyond must treat checklists not as static to-dos, but as dynamic decision engines that continuously learn and improve. AI-enabled checklists power smarter maintenance strategies, drive continuous improvement, and unlock operational reliability at scale.

For enterprises serious about reliability, efficiency, and digital transformation, integrating smart checklists into a full AI-driven CMMS like MaintWiz is not just better—it’s essential.