Lubrication Neglect Causes More Downtime Than AI Ever Will

Lubrication problems aren’t just a maintenance nuisance — they are a systemic reliability risk that costs industrial plants millions every year. While buzzwords like AI predictive analytics and digital twins dominate executive meetings, actual asset reliability still hinges on fundamentals like lubrication management. In this in-depth article, we explore why lubrication neglect remains a top killer of uptime, how OEMs and operators can eliminate this hidden risk, and why the MaintWiz CMMS solution delivers the right blend of fundamentals and technology to transform maintenance outcomes.

Why Lubrication Neglect Is Still the #1 Reliability Killer

Overview

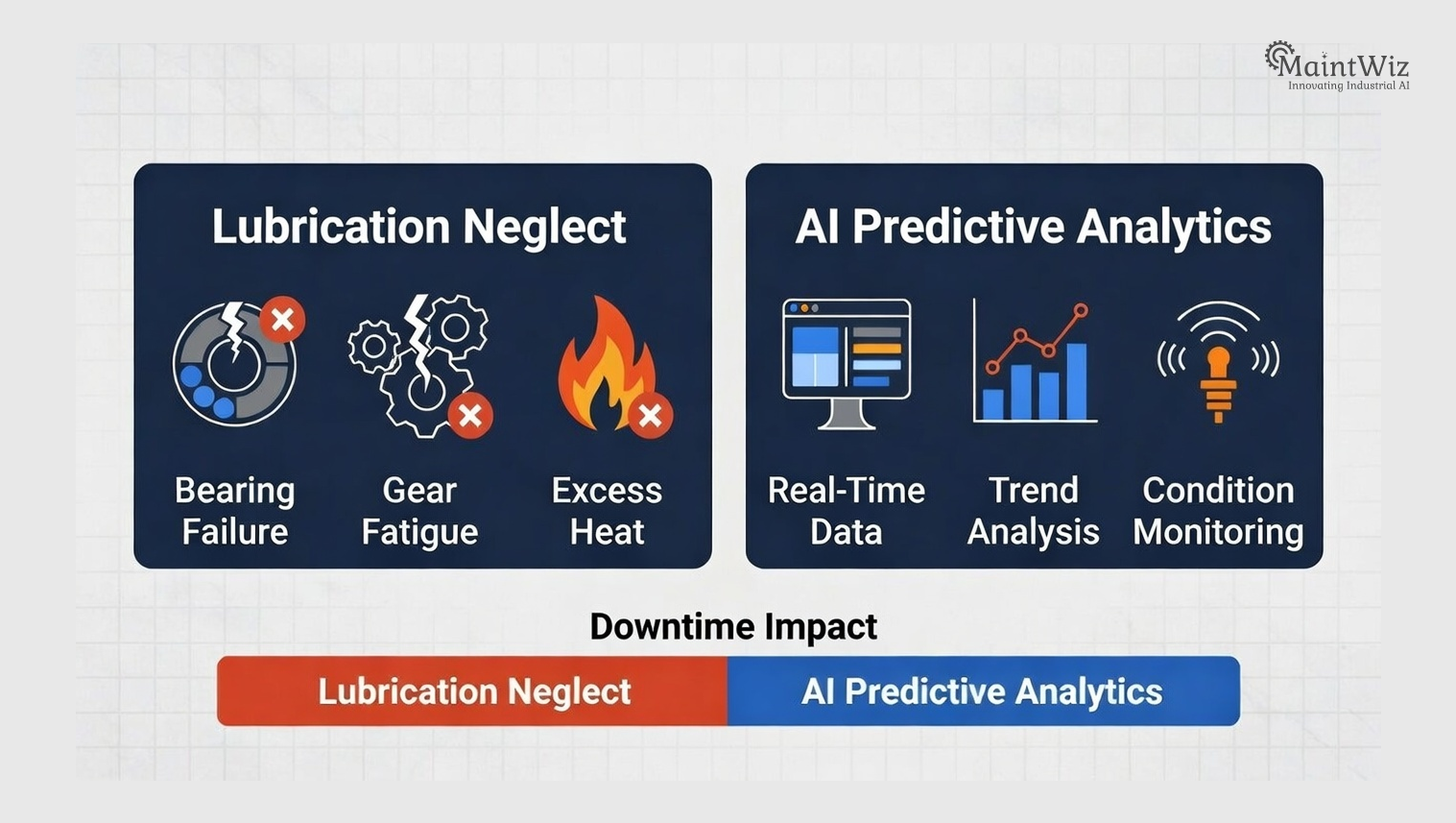

Despite decades of automation and digital transformation, lubrication mismanagement remains one of the leading causes of asset failure. Studies in industrial maintenance consistently show that a large proportion of bearing failures — in some cases 60–80% — are directly linked to improper lubrication practices including contamination, under-lubrication, or over-lubrication.

Lubrication neglect might seem like a “low tech” issue, but its effects are anything but trivial. Poor lubrication creates friction, heat, wear, and premature failure — factors that directly contribute to unplanned downtime, repair costs, and safety risk.

The Mechanics of Downtime

- Bearing Failure Due to Under-Lubrication

When lubricants are insufficient or inconsistently applied, components like bearings and gears quickly deteriorate, increasing friction and heat which accelerate wear. - Contamination and Degradation

Lubricants that are contaminated with particles, moisture, or incompatible additives lose effectiveness, leading to internal abrasion and shortened service life. - Over-Lubrication Risks

Too much grease or oil causes seal failures and increased drag, which not only wastes material but also stresses bearings and accelerates failure. - Skipped or Deferred Lubrication Tasks

In reactive work environments where preventive routines are deprioritized, lubrication tasks are the first to be missed — often with catastrophic results.

The bottom line: A lubricant misapplied is a component prematurely condemned. Until lubrication is managed with discipline and data, downtime will persist regardless of AI investments.

From Reactive to Predictive: The Role of Modern Maintenance

Overview

The evolution of maintenance management has moved from reactive firefighting to predictive and condition-based approaches. While AI has advanced the field tremendously, it’s essential to understand where AI fits — and where it does not replace foundational practices like lubrication.

Predictive maintenance strategies leverage data from sensors, historical performance, and machine patterns to forecast failure before it happens. But even in the most advanced facilities, sensors can alert you that a bearing is overheating — but if lubrication practices are lax, the warning comes too late.

Maintenance Approaches Compared

- Reactive Maintenance

Firefighting mode: fix only when broken. This approach increases unplanned downtime and repair costs. - Preventive Maintenance

Time-based lubrication schedules ensure regular attention, but lack flexibility without data integration. - Predictive Maintenance

Condition-based alerts reduce surprises, but still depend on accurate data and consistent execution by technicians. - AI-Driven Maintenance (CMMS + Analytics)

Tools like MaintWiz CMMS combine AI foresight with operational data to optimize lubrication schedules, detect anomalies, and integrate work orders — delivering reliability with precision.

Key Insight: Predictive analytics improves uptime more when anchored to sound maintenance practices such as lubrication discipline — it does not replace them.

The Invisible Costs of Ignoring Lubrication

Overview

When lubrication is treated as a “routine checkbox task,” its broader impact on operations and business performance is underestimated. The real costs are seldom fully quantified — but they manifest as measurable declines in asset life, unscheduled stoppages, and lost production.

Compounding Impact on Operations

- Unplanned Downtime and Production Loss

A single lubrication-related failure can halt production lines for hours or days, resulting in cascading scheduling challenges. - Reduced Asset Lifespan

Components that operate under poor lubrication conditions wear out faster, driving more frequent replacements and higher capital expenses. - Maintenance Cost Escalation

Reactive repairs after failure cost significantly more than planned lubrication and minor corrective actions. - Safety and Compliance Risks

Mismanaged lubrication increases heat and friction, elevating fire risk and non-compliance with safety audits and standards. - Executive Attention Shifts to High-Tech Solutions

Leadership often chases shiny new technologies like AI predictive analytics or digital twins while ignoring the daily execution quality of basic tasks like lubrication routines — leading to investment mismatches.

Best Practices in Lubrication Management for Industrial Assets

Overview

Bringing lubrication out of the shadows requires disciplined strategy, proper measurement, and technology-enabled workflows. Below are proven approaches to ensure lubrication management supports reliability goals.

Key Lubrication Strategies

- Standardize Lubricant Selection and Storage

Use specified lubricants per OEM and store them correctly to prevent contamination, ensuring each asset receives the right fluid for its operating conditions. - Define Clear Application Protocols

Specify the correct quantity, frequency, and method for lubrication tasks — too much or too little can both be harmful. - Use Condition Data to Trigger Lubrication Tasks

Instead of static schedules, integrate condition-based triggers (e.g., temperature, vibration trends) to optimize lubrication events. - Train Technicians on Proper Techniques

Provide regular training for technicians on lubrication practices, emphasizing the science behind the task and not just the checklist. - Monitor and Review Lubrication Outcomes

Regularly analyze work order history and lubrication outcomes to spot patterns that can inform continuous improvement.

Objective: Elevate lubrication from a routine task to a reliability-centric practice with measurable impact.

How AI and CMMS Technology Enhance Lubrication Management

Overview

AI and CMMS systems, when applied judiciously, amplify the impact of good lubrication practices. They don’t replace fundamental maintenance — they enhance precision, visibility, and execution.

Technology Benefits for Lubrication Control

- AI-Driven Condition Insights

AI analytics detect deviations that may signal lubrication issues before failures occur. - Automated Work Order Generation

Systems like MaintWiz CMMS automatically schedule lubrication tasks based on analytics and condition triggers, reducing manual errors. - Real-Time Alerts and Notifications

Teams receive timely alerts for lubrication needs, improving responsiveness and task adherence. - Integration With Predictive Maintenance Workflows

Combining lubricant condition data with predictive analytics creates a holistic view of asset health. - Mobile Access for Field Technicians

Mobile CMMS access enables technicians to update lubrication tasks on the ground, ensuring accurate and timely execution.

The synergy: Human expertise + CMMS automation + AI insights = lubrication practices that deliver measurable uptime gains.

Real-World Reliability Gains from Better Maintenance Practices

Overview

Leading industrial organizations demonstrate that when lubrication management is properly aligned with maintenance strategy and technology, operational performance significantly improves. Case studies consistently show reductions in failures, longer asset life, and improved OEE — even when basic lubrication gets elevated in importance.

Measurable Improvements

- Reduced Unplanned Downtime: Companies with data-driven lubrication and preventive routines see significant reductions in unexpected stoppages.

- Extended Asset Lifecycle: Better lubrication management enhances component durability and reduces replacements.

- Improved Maintenance Efficiency: Time saved from repeat failures enables teams to focus on strategic work.

- Enhanced Safety and Compliance: Predictable lubrication routines support audit readiness and safety performance.

Why MaintWiz CMMS Is the Right Solution for Reliability-Driven Plants

Overview

Given the central role lubrication plays in uptime, a maintenance platform must do more than automate work orders — it must enable data-driven decision-making, integrated workflows, and continuous improvement. MaintWiz CMMS is designed to address these needs and more.

What Makes MaintWiz CMMS Exceptional

- Comprehensive Asset Management

MaintWiz consolidates asset data, maintenance tasks, lubrication records, and analytics in one unified platform. - AI-Powered Predictive Maintenance

The system uses advanced AI to analyze condition indicators, optimize lubrication schedules, and reduce unplanned downtime. - Automated Work Order & Scheduling

Intelligent scheduling reduces manual errors and ensures lubrication tasks are prioritized based on real needs. - Mobile-Enabled Execution

Field technicians get real-time access to work orders and lubrication history, improving execution and data accuracy. - Seamless Integration With Systems (SAP, IoT)

MaintWiz integrates with enterprise systems to ensure lubrication and maintenance data flow smoothly across operations. - Advanced Analytics and Dashboards

Real-time dashboards provide visibility into KPIs such as MTTR, asset health trends, and lubrication compliance. - Continuous Improvement Support

By tracking outcomes over time, MaintWiz enables teams to refine lubrication strategies and achieve reliability excellence.

In essence: MaintWiz bridges the gap between essential maintenance fundamentals and advanced predictive capabilities, helping plants turn lubrication from an afterthought into a strategic reliability advantage.

Jai Balachandran is an industry expert with a proven track record in driving digital transformation and Industry 4.0 technologies. With a rich background in asset management, plant maintenance, connected systems, TPM and reliability initiatives, he brings unparalleled insight and delivery excellence to Plant Operations.