The #1 Reason Your Plant’s MRO Budget Exploded (And How to Fix It)

Industrial plants across manufacturing, utilities, energy, and process industries are facing a harsh reality: MRO budgets are rising faster than production, margins are shrinking, and reliability targets are getting harder to meet.

Most leaders respond the same way—freeze hiring, delay preventive maintenance, renegotiate vendor contracts, or pressure maintenance teams to “do more with less.” And yet, costs continue to spiral.

Here’s the uncomfortable truth few organizations are willing to confront:

Your MRO budget didn’t explode because maintenance is inefficient. It exploded because your maintenance operating model is fundamentally reactive.

This article explains why that happens, where the real money is lost, and how modern, AI-driven CMMS platforms like MaintWiz are helping plants regain control—not by cutting maintenance, but by making it intelligent.

Understanding the MRO Budget Explosion: Why This Problem Is So Widespread

Overview: Why even “well-run” plants lose control of MRO costs

MRO (Maintenance, Repair, and Operations) spending is often treated as an unavoidable cost of doing business. Yet global benchmarks show that plants with similar asset profiles can differ by 20–40% in maintenance costs. The difference is rarely effort—it’s structure.

Key reasons MRO budgets quietly spiral:

- Maintenance decisions are event-driven, not

risk-driven

Most spending decisions occur after failures, not before. By the time action is taken, costs are already inflated. - Downtime costs are underestimated or ignored

Production losses, quality deviations, and safety risks rarely show up in maintenance budgets—but they are real economic losses. - CMMS systems track history but don’t predict the future

Traditional systems document what happened, not what’s about to happen. - Asset behavior has changed—but maintenance logic hasn’t

Higher utilization, automation, and tighter tolerances have increased failure complexity.

The #1 Root Cause: Reactive Maintenance Culture

Overview: The invisible operating model behind rising MRO costs

Reactive maintenance isn’t just a tactic—it’s a culture. It’s how priorities are set, how work is approved, and how success is measured.

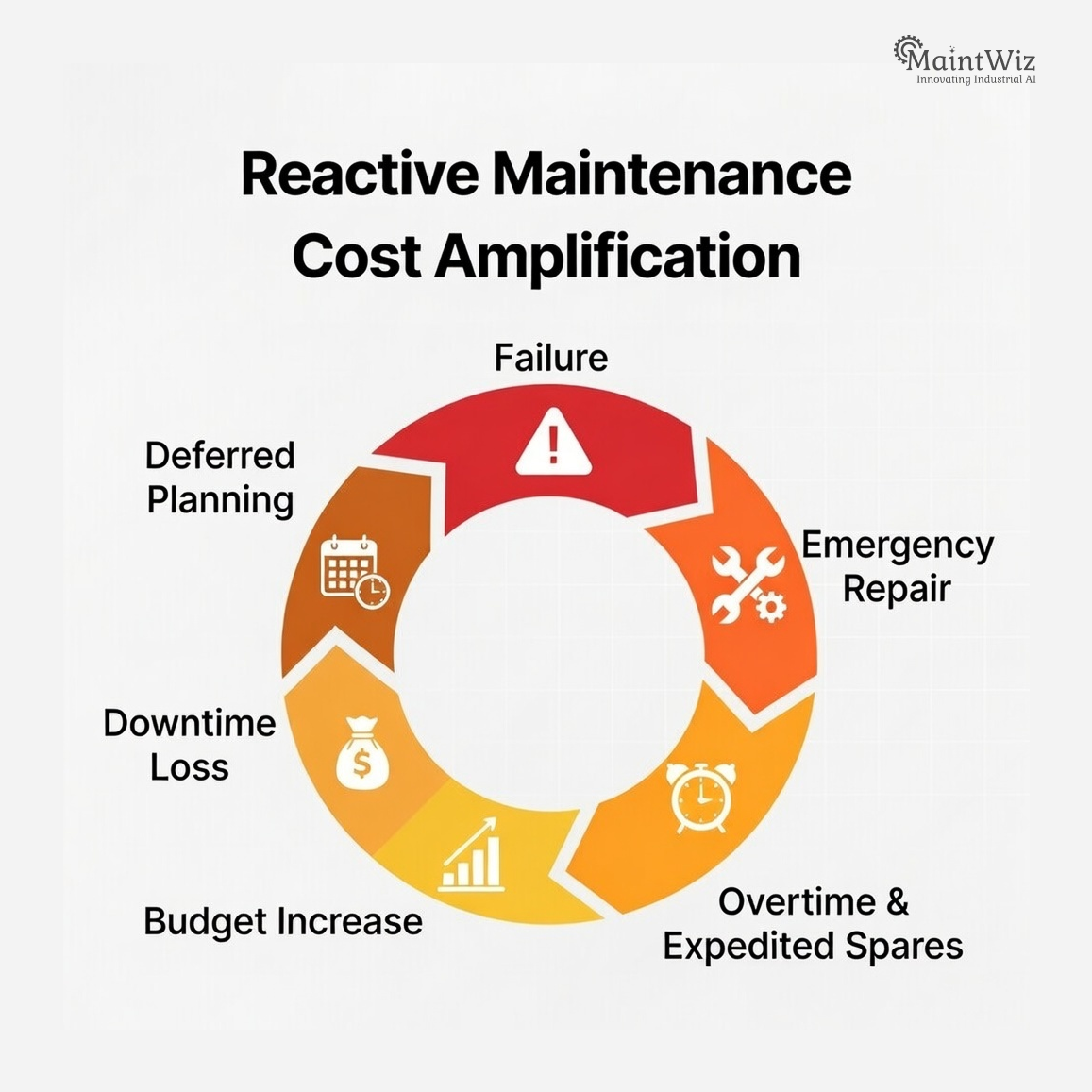

How reactive maintenance drives budget explosion:

- Breakdowns trigger spending, not planning

Emergency repairs cost exponentially more due to overtime labor, expedited parts, and rushed execution. - Maintenance work bypasses prioritization discipline

Emergency work orders leapfrog planned tasks, creating backlog instability. - Failures repeat because root causes are not addressed

Teams fix symptoms quickly but rarely eliminate systemic issues. - Heroic firefighting is rewarded over prevention

Organizational behavior reinforces reaction, not foresight.

Reactive maintenance is not cheaper maintenance—it is delayed and amplified maintenance.

Why Preventive Maintenance Alone No Longer Works

Overview: The limits of calendar-based maintenance

Many organizations believe they are proactive because they run preventive maintenance (PM) programs. Yet PM alone often fails to control costs.

Why traditional preventive maintenance falls short:

- Time-based schedules ignore asset condition

Equipment doesn’t fail by calendar—it fails by stress, load, and degradation. - Over-maintenance wastes labor and spare parts

Assets are serviced unnecessarily, inflating costs without reducing risk. - Under-maintenance misses early failure signals

Critical degradation between PM intervals goes unnoticed. - PM compliance masks poor asset health

High PM completion rates create false confidence.

The Economic Difference Between Reactive and Predictive Maintenance

Overview: Why timing—not effort—determines cost

The single biggest lever in maintenance economics is when intervention occurs.

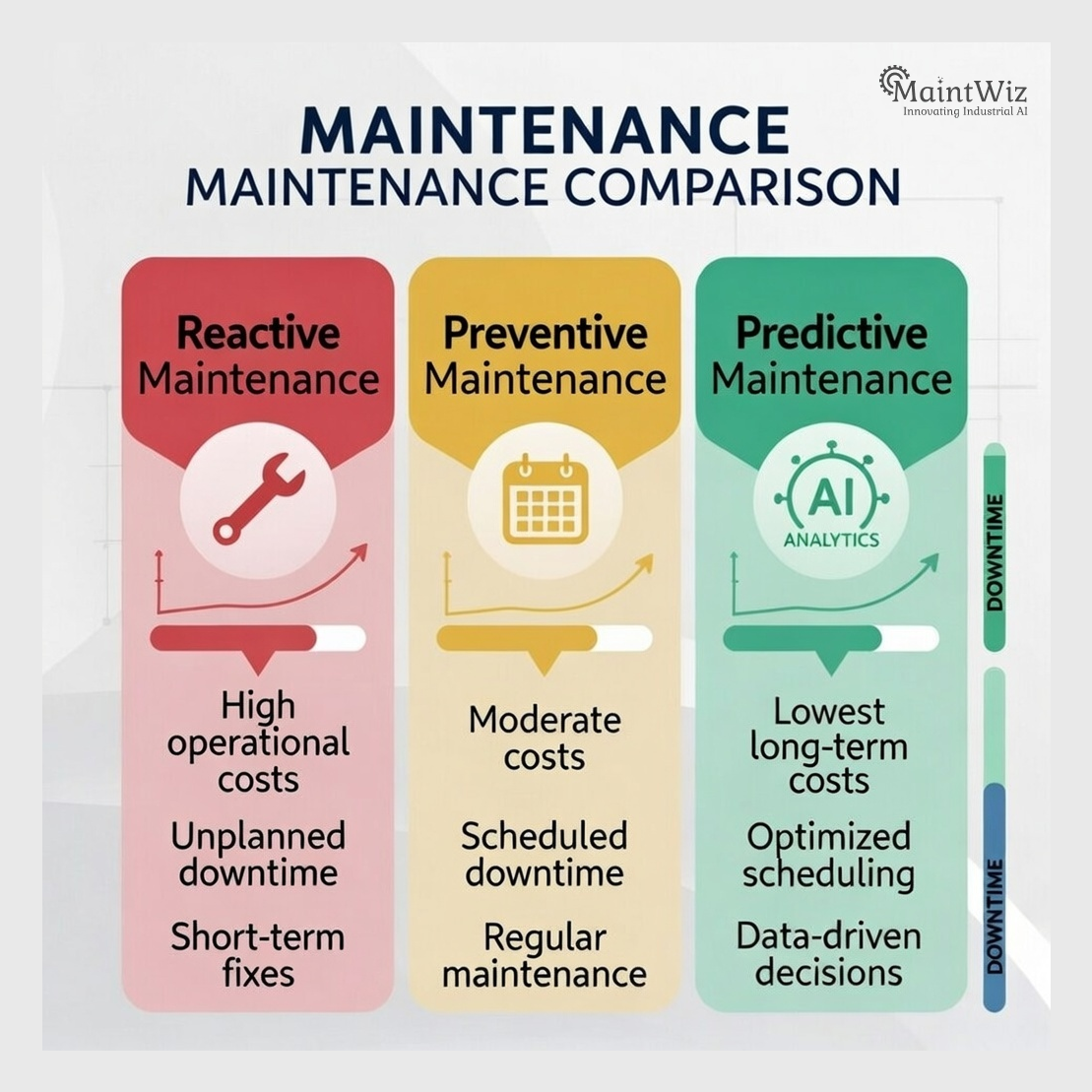

Cost dynamics by maintenance strategy:

- Reactive maintenance: Highest cost per event

Emergency labor, downtime losses, and safety exposure dominate. - Preventive maintenance: Moderate cost, inconsistent benefit

Costs are stable, but failures still occur unexpectedly. - Predictive maintenance: Lowest total cost

Early detection enables planned intervention at minimal disruption.

Predictive maintenance doesn’t reduce work—it shifts work to the cheapest possible moment.

Why Legacy CMMS Systems Fail to Stop MRO Budget Growth

Overview: Record-keeping is not intelligence

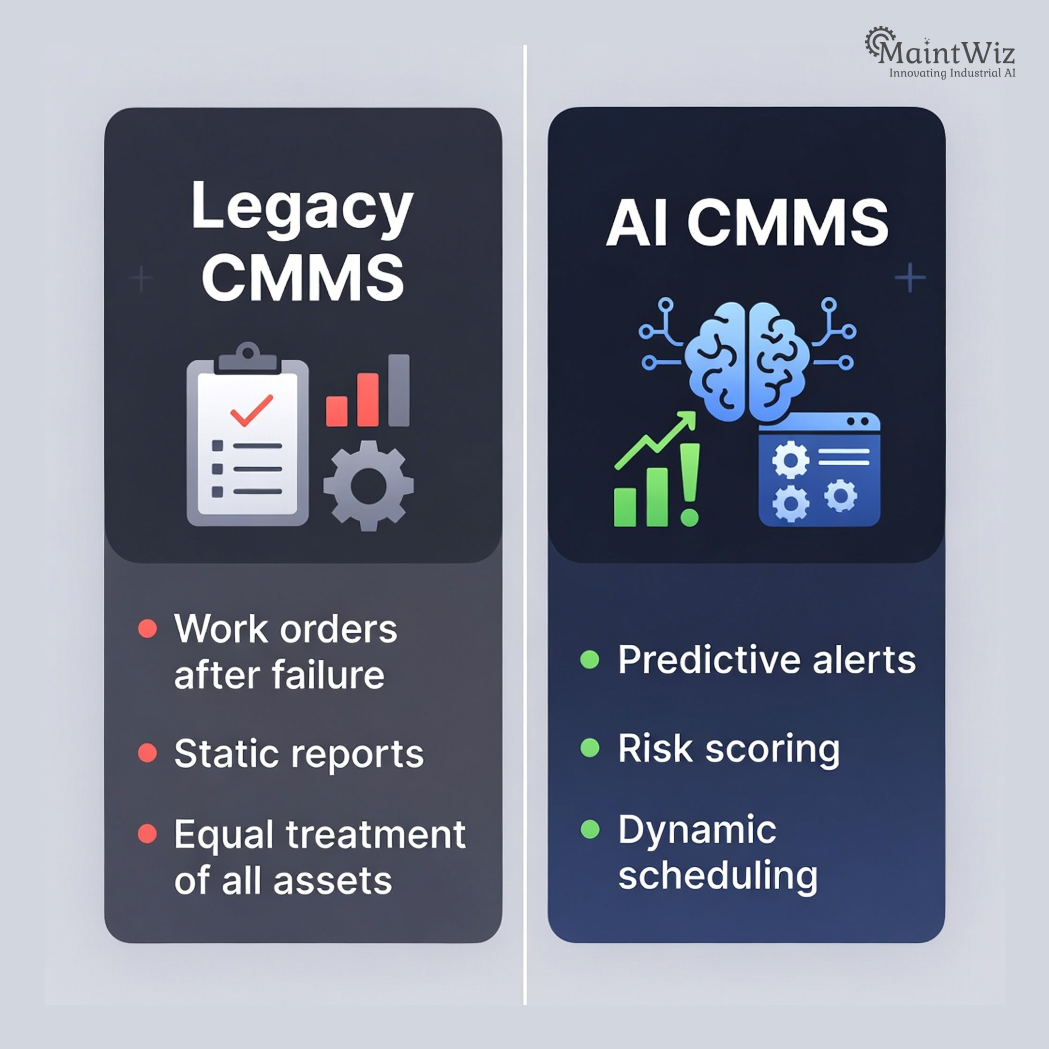

Most CMMS platforms were designed decades ago to log work orders and track PM schedules. That design limitation is now a financial liability.

Structural limitations of legacy CMMS:

- Reactive workflows embedded in system logic

Work orders are created after failure events. - Limited analytics and static KPIs

Reports describe the past but offer no foresight. - No failure prediction or risk scoring

All assets are treated equally, regardless of criticality. - Disconnected asset, inventory, and workforce data

Decisions are made in silos.

The Rise of AI-Driven CMMS and Intelligent Maintenance

Overview: Maintenance is becoming a data science problem

Modern plants generate massive volumes of asset data—from sensors, PLCs, historians, and operational systems. AI-driven CMMS platforms convert this data into decisions.

What intelligent maintenance enables:

- Predictive failure detection

AI identifies abnormal patterns before functional failure. - Risk-based work prioritization

Maintenance resources focus on assets that matter most. - Dynamic maintenance scheduling

Plans adjust automatically as conditions change. - Continuous learning from asset behavior

Models improve as more data is collected

Asset Management: The Missing Link in MRO Cost Control

Overview: Maintenance costs follow asset decisions

Maintenance is downstream of asset management. Poor asset data guarantees poor maintenance decisions.

How asset intelligence reduces MRO spend:

- Digital asset registers with full lifecycle history

Visibility into performance, failures, and costs. - Asset criticality analysis

Maintenance intensity aligns with business risk. - Failure mode tracking and pattern recognition

Prevents repeat failures. - Lifecycle-based replacement planning

Avoids excessive repair of end-of-life assets.

Workforce Optimization: Where Hidden Costs Accumulate

Overview: Labor is the largest controllable MRO expense

Labor inefficiency is rarely due to people—it’s due to planning.

Workforce challenges that inflate MRO budgets:

- Skill mismatches increase MTTR

Wrong technician assignments prolong repairs. - Overtime hides planning failures

Short-term fixes create long-term cost inflation. - Tribal knowledge remains undocumented

Expertise is lost when employees leave. - No predictive labor planning

Staffing reacts to failures instead of forecasts.

(Explore: AI-Driven Workforce Management in MaintWiz)

Inventory Optimization: The Silent MRO Budget Killer

Overview: Spare parts inefficiency drains working capital

Inventory decisions are often disconnected from asset health.

Common inventory cost drivers:

- Overstocking to avoid downtime

Ties up cash and increases obsolescence. - Stockouts during emergencies

Forces premium purchases. - Forecasting based on history, not condition

Ignores real failure risk. - Poor visibility across sites

Duplicate inventory inflates spend.

(See: Inventory Management with MaintWiz CMMS)

KPIs That Actually Control MRO Budgets

Overview: Measure what predicts cost—not what explains it

Lagging indicators describe history. Leading indicators control the future.

High-impact maintenance KPIs:

- Planned vs Unplanned Maintenance Ratio

Measures predictability. - Mean Time Between Failures (MTBF)

Tracks asset reliability. - Mean Time to Repair (MTTR)

Reflects workforce effectiveness. - Maintenance Cost per Asset

Enables asset-level decisions. - Predictive vs Reactive Work Percentage

Indicates maturity.

What World-Class Plants Do Differently

Overview: A fundamentally different mindset

Top performers don’t “manage maintenance”—they manage risk.

Hallmarks of high-performing organizations:

- Failures are treated as preventable events

- Maintenance is aligned with production strategy

- Data challenges intuition

- Reliability metrics are reviewed at executive level

- Technology amplifies decision-making, not paperwork

Why MaintWiz CMMS Is Built for This New Reality

Overview: From maintenance software to maintenance intelligence

MaintWiz CMMS is designed to help organizations move from reactive firefighting to predictive, data-driven asset stewardship.

How MaintWiz addresses the root causes of MRO budget explosion:

- AI-Powered Predictive Maintenance

Anticipates failures before downtime occurs. - End-to-End Asset Lifecycle Management

Connects performance, cost, and reliability data. - Smart Work Order Prioritization

Focuses resources where risk is highest. - Integrated Workforce Intelligence

Matches skills, availability, and urgency. - Advanced Inventory Optimization

Aligns spares with failure probability. - Mobile-First Execution

Empowers technicians with real-time insights. - Executive Dashboards and Analytics

Enables confident, data-driven decisions.

MaintWiz doesn’t reduce maintenance—it eliminates waste, uncertainty, and surprise.

Final Thought: MRO Budgets Don’t Explode—Systems Do

If your MRO budget feels out of control, the answer is not tighter controls or smaller teams. The answer is better intelligence.

Reactive maintenance is expensive not because people work hard—but because they work too late.

Predictive, AI-driven maintenance—enabled by platforms like MaintWiz CMMS—turns maintenance from a cost center into a competitive advantage.

Jai Balachandran is an industry expert with a proven track record in driving digital transformation and Industry 4.0 technologies. With a rich background in asset management, plant maintenance, connected systems, TPM and reliability initiatives, he brings unparalleled insight and delivery excellence to Plant Operations.