What TPM Looks Like When You’re Short-Staffed and Still Make It Work

Total Productive Maintenance (TPM) has long been heralded as a foundational strategy for reliability, zero unplanned downtime, and continuous improvement. Yet, on real shop floors, especially those that operate with lean teams, classic TPM implementations often struggle. In this article, we dissect what TPM looks like when staff levels are limited — and how organizations not only survive but excel by leveraging smart strategies, process discipline, and cutting-edge tools such as MaintWiz AI CMMS.

The Challenge of TPM in Resource-Constrained Environments

Overview

TPM requires commitment, cross-functional involvement, and proactive execution. However, lean maintenance teams face specific constraints: high reactive workloads, limited manpower for preventive tasks, and difficulty maintaining documentation and process discipline.

Why Traditional TPM Struggles With Lean Teams

- Reactive Work Dominates Daily Time

Without adequate staffing, teams spend the majority of their time responding to breakdowns rather than preventive and autonomous maintenance. - Documentation Lags Behind Execution

TPM relies on accurate reporting of failures, corrective actions, and improvements — which often falls through the cracks when teams are stretched. - Scheduling Complexity Overwhelms Staff

Effective TPM demands optimized maintenance scheduling, but manual systems or spreadsheets rarely keep up with dynamic shop floor demands. - Knowledge Loss Between Shifts

When shift changes occur without structured digital handoffs, valuable insights and observations are lost — undermining continuous improvement.

Understanding these core bottlenecks is the first step toward tailoring TPM practices that work even when headcount is limited.

Rethinking TPM: Core Principles That Work When You’re Short-Staffed

Overview

Effective TPM isn’t about completing every theoretical pillar with perfection — it’s about prioritizing work that delivers immediate reliability impact, standardizing routine tasks, and strategically automating repetitive processes.

6 Practical Lean TPM Strategies

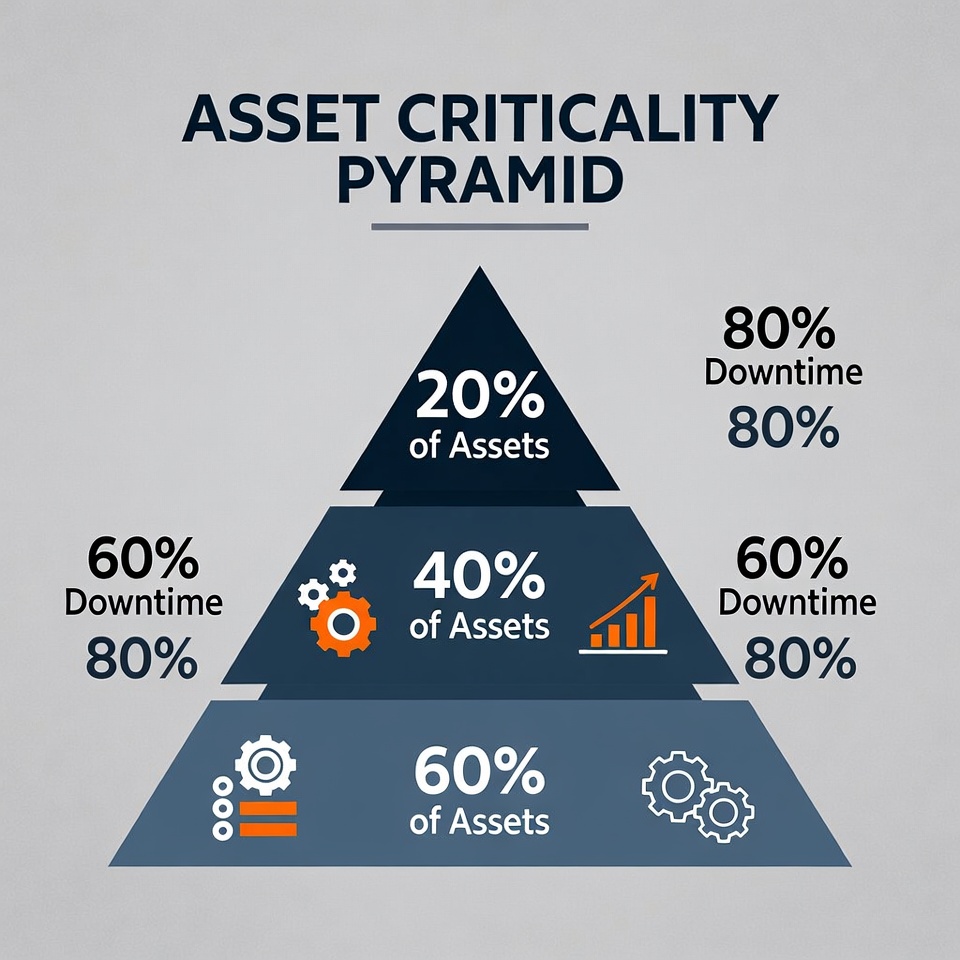

- Critical Asset Prioritization

Focus your limited workforce on high-impact equipment that drives production continuity. - Simplified Standard Operating Procedures (SOPs)

Short, clear, and visual SOPs ensure consistency in execution despite lean staffing. - Automated Scheduling and Alerts

Replace manual planning with intelligent automation to ensure that maintenance tasks are triggered with precision and timeliness. - Mobile Execution and Real-Time Updates

Allow technicians to execute, update, and close tasks from the shop floor — eliminating delays and miscommunication. - Continuous Improvement Through Daily Routines

Instead of periodic TPM events, tie improvements to routine tasks and shift handovers. - Cross-Training and Skill Sharing

Enable flexibility by ensuring technicians are prepared to handle a broader range of tasks.

These strategies shift TPM from an idealized framework to a practical, shop floor-ready model.

Digital Transformation: A TPM Enabler — Not a Replacement

Overview

Digital tools don’t replace TPM — they magnify its impact, especially for lean teams. A Computerized Maintenance Management System (CMMS) centralizes knowledge, automates mundane tasks, and provides real-time visibility into asset health, workforce performance, and maintenance outcomes.

Why TPM Must Be Digital-Ready

- Real-Time Asset Condition Monitoring

Live alerts and sensor data help maintenance teams act before equipment failure. - Automated Preventive Maintenance Scheduling

Systems can generate work orders based on usage, condition, or time triggers. - Workflow Standardization Across Shifts

Consistent digital workflows ensure that TPM tasks are performed the same way regardless of who’s on duty. - Centralized Work Order Management

Monitor task status, assignments, and execution history in one place. - Inventory and Resource Optimization

Knowing which parts are needed ahead of time helps avoid delays and emergency purchases.

When teams are limited, automation and real-time intelligence become non-negotiable tools for TPM success.

The TPM Benefits You Can Realize — Even With Limited Staff

Overview

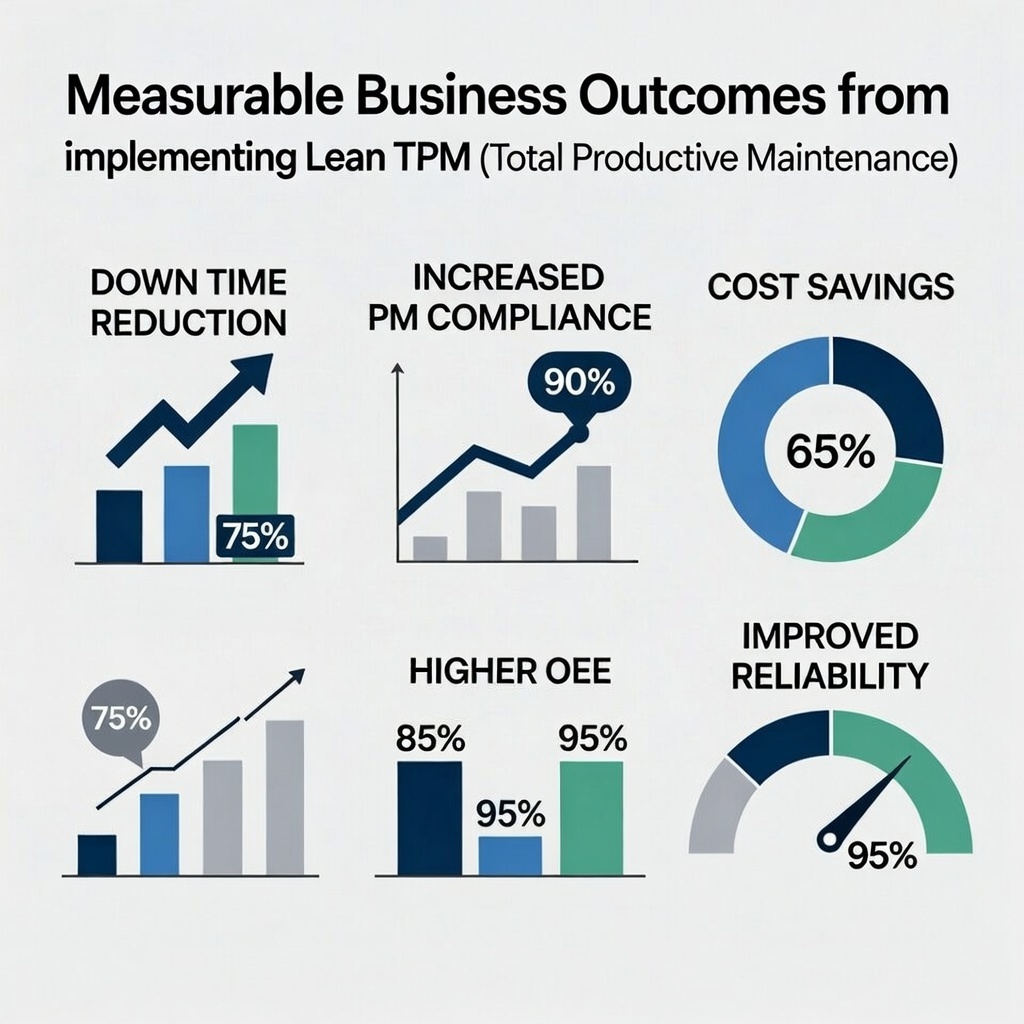

Leaner teams often produce better results than larger ones — not because they work harder, but because they work smarter. TPM enhanced with digital tools yields measurable benefits.

Key TPM Outcomes for Lean Maintenance

- Reduced Unplanned Downtime

Predictive and preventive strategies lower the frequency of disruptions. - Extended Asset Lifespan

Regular maintenance based on actual conditions, not schedules, prevents early wear. - Higher Equipment Effectiveness

TPM improves Overall Equipment Effectiveness (OEE), even in understaffed environments. - Lower Maintenance Costs

Fewer emergency repairs and optimized parts usage translate to healthier financial outcomes. - Improved Operational Predictability

Maintenance becomes scheduled, not reactive — freeing up your team to focus on value-driving work.

These outcomes validate TPM as more than a framework — it becomes an operational multiplier when executed right.

Why MaintWiz AI CMMS Powers Lean TPM Success

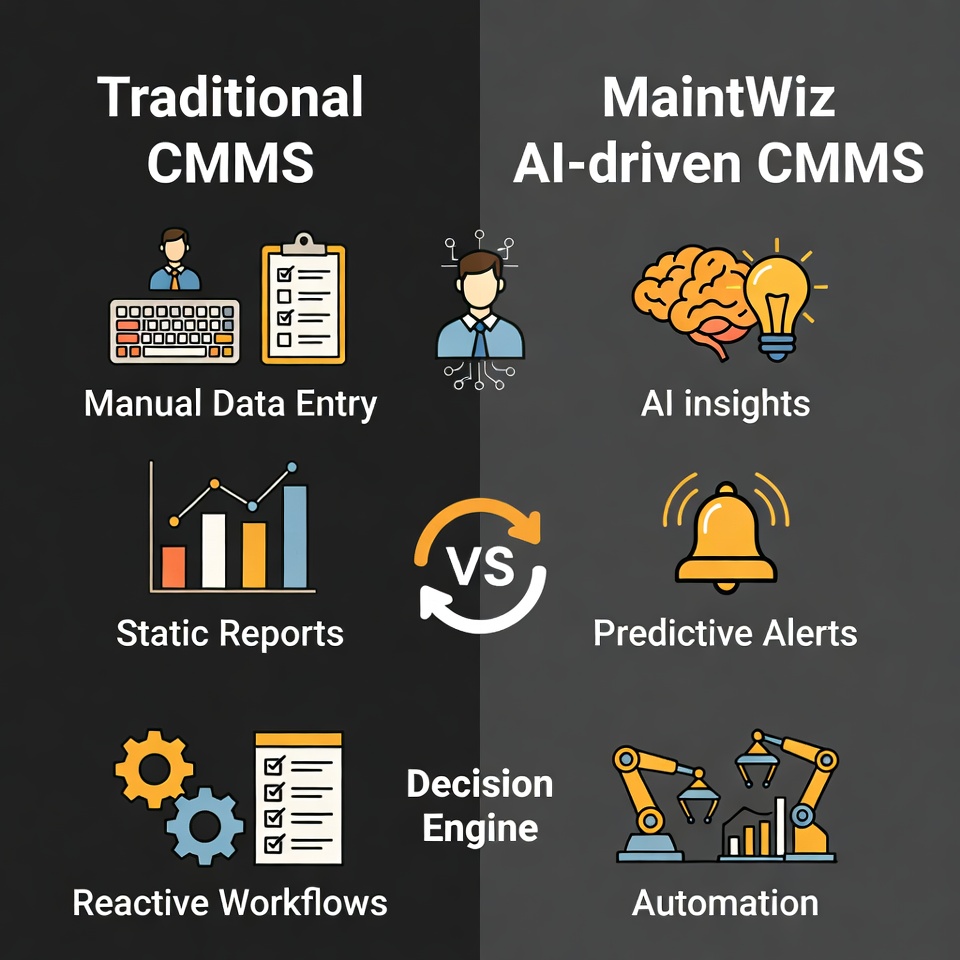

Overview

MaintWiz AI CMMS is an AI-driven maintenance management platform that helps teams bridge the gap between lean staffing and robust TPM outcomes. Unlike traditional CMMS solutions that are passive recordkeepers, MaintWiz integrates real-time analytics, intelligent scheduling, and mobile execution capabilities — all designed to make TPM a living, operational reality.

Below are the key features that make MaintWiz indispensable for TPM excellence:

- Smart Predictive Maintenance Analytics

MaintWiz leverages AI to predict equipment failures before they occur, allowing lean teams to be proactive — not reactive.

- Automated and Priority-Based Scheduling

Work orders are generated and prioritized based on equipment criticality and operational impact — ensuring that the team always works on the most valuable tasks.

- Mobile-Enabled Work Order Execution

Technicians can access work orders, update tasks, and capture data from anywhere on the shop floor.

- Real-Time Asset Health Monitoring

Integration with IoT sensors provides continuous condition data, enabling early intervention and fewer breakdowns.

- Workforce Optimization Tools

MaintWiz intelligently matches tasks with technician skills, ensuring efficient use of lean resources.

- Integrated Inventory and Spare Parts Management

Ensure critical parts are available when needed — reducing downtime caused by stockouts.

- Support for TPM Framework Tasks

MaintWiz provides tools for 5S, Kaizen tracking, loss reduction analysis, and TPM audit reporting — helping you track improvement initiatives with precision.

Investing in a robust, intelligent CMMS doesn’t add complexity — it simplifies execution so your lean team can focus on work that drives real value.

How to Get Started with Lean TPM and MaintWiz

Practical Implementation Steps

- Map Your Critical Assets

Identify which machines drive the most value and require prioritized attention. - Digitize Workflows

Move all maintenance tasks, logs, and schedules into MaintWiz CMMS. - Enable Condition Monitoring

Integrate sensors or data feeds to track equipment health in real time. - Automate Preventive Work Orders

Set up schedules based on usage data and condition thresholds. - Train Your Team

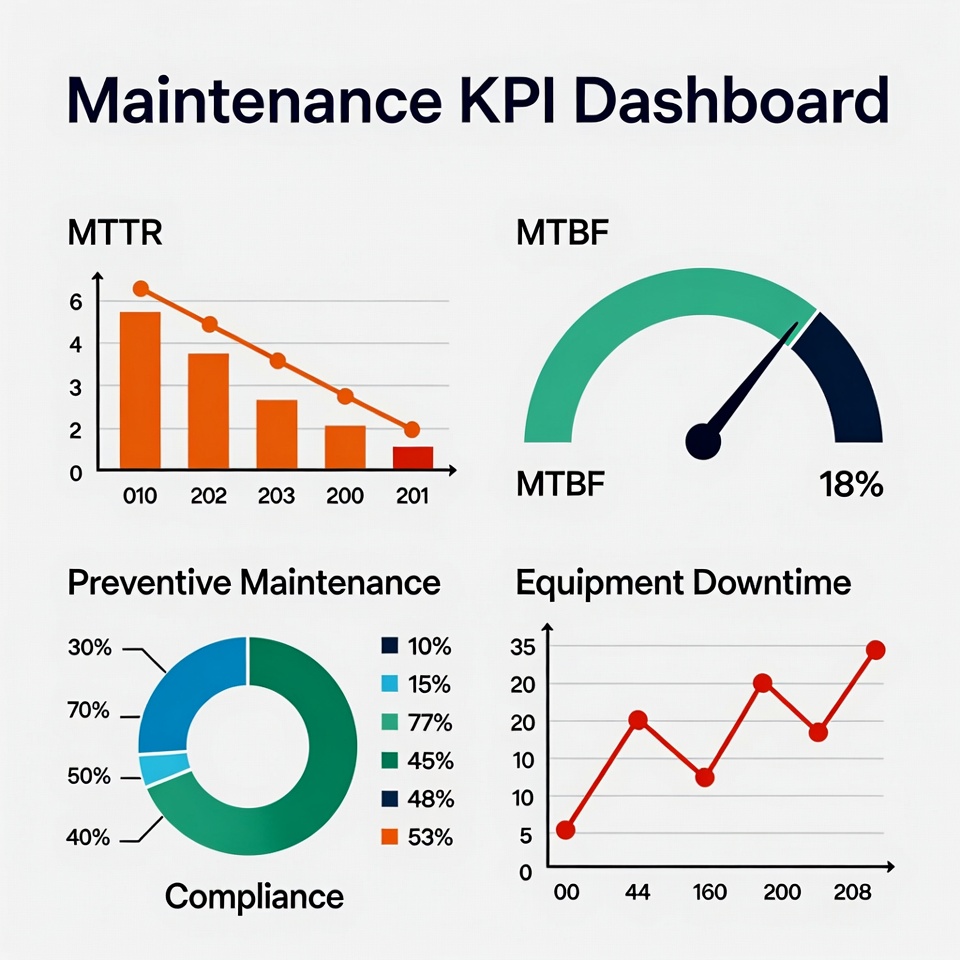

Ensure every technician can use mobile tools for execution and updates. - Review KPIs Regularly

Use dashboards for MTTR, uptime, schedule compliance, and continuous improvement insights.

This structured approach ensures your TPM adoption is rapid, measurable, and resilient — even with limited staff.

Conclusion

TPM can and should work even when your maintenance team is lean. By prioritizing critical assets, standardizing maintenance workflows, and embracing digital tools like MaintWiz AI CMMS, organizations can transform reliability strategies from theoretical frameworks into operational reality.

Lean TPM is not about doing everything — it’s about doing right things consistently. With the right strategy and tools, your team can reduce downtime, extend equipment life, and drive continuous improvement — all without adding headcount.