Elevate Batch Processing Efficiency with MaintWiz AI CMMS

Unlock unprecedented operational excellence in batch manufacturing. MaintWiz AI CMMS optimizes asset performance, ensures regulatory compliance, and drives productivity across your batch processing facilities.

Transformative Benefits of MaintWiz AI CMMS for Batch Processing

Revolutionizing Batch Processing Maintenance

Maximize Asset Utilization and Uptime

MaintWiz AI CMMS employs predictive analytics to forecast equipment failures, optimizing maintenance schedules and minimizing costly downtime in your batch processing operations.

Ensure Batch-to-Batch Consistency

Our intelligent system monitors equipment performance, ensuring consistent product quality across batches and reducing variability in your manufacturing processes.

Streamline Regulatory Compliance

MaintWiz automates documentation and provides real-time tracking of maintenance activities, simplifying adherence to FDA, GMP, and other industry-specific regulations.

Optimize Resource Allocation

Leverage AI-driven insights to efficiently allocate maintenance resources, balancing workload and minimizing disruptions to your batch processing schedule.

Enhance Operational Flexibility

Adapt swiftly to changing production demands with MaintWiz’s dynamic maintenance planning, supporting agile batch manufacturing processes.

Top Companies in India & Abroad Trust MaintWiz CMMS

Speak to a Specialist

Get personalised advice from our experts

Why MaintWiz AI CMMS is the Cornerstone of Batch Processing Excellence

Experience a paradigm shift in batch processing maintenance with MaintWiz's cutting-edge AI-powered solutions tailored for your industry's unique challenges.

Transforming Every Stage of Your Batch Processing Operations

MaintWiz AI CMMS delivers targeted solutions for each critical phase of your batch manufacturing process, ensuring seamless operations from raw material handling to final product packaging.

Raw Material Handling and Storage

- Optimize inventory management with predictive maintenance insights

- Ensure proper storage conditions through proactive equipment monitoring

- Streamline material flow with AI-driven maintenance scheduling

- Reduce contamination risks through rigorous equipment upkeep

Batch Preparation and Mixing

- Maintain precise equipment calibration for consistent batch quality

- Minimize downtime of critical mixing and blending equipment

- Ensure optimal performance of CIP/SIP systems

- Proactively address potential issues in batch reactors

Process Control and Monitoring

- Integrate maintenance data with process control systems

- Enhance reliability of sensors and control equipment

- Optimize performance of batch sequencing systems

- Ensure accuracy of in-process testing equipment

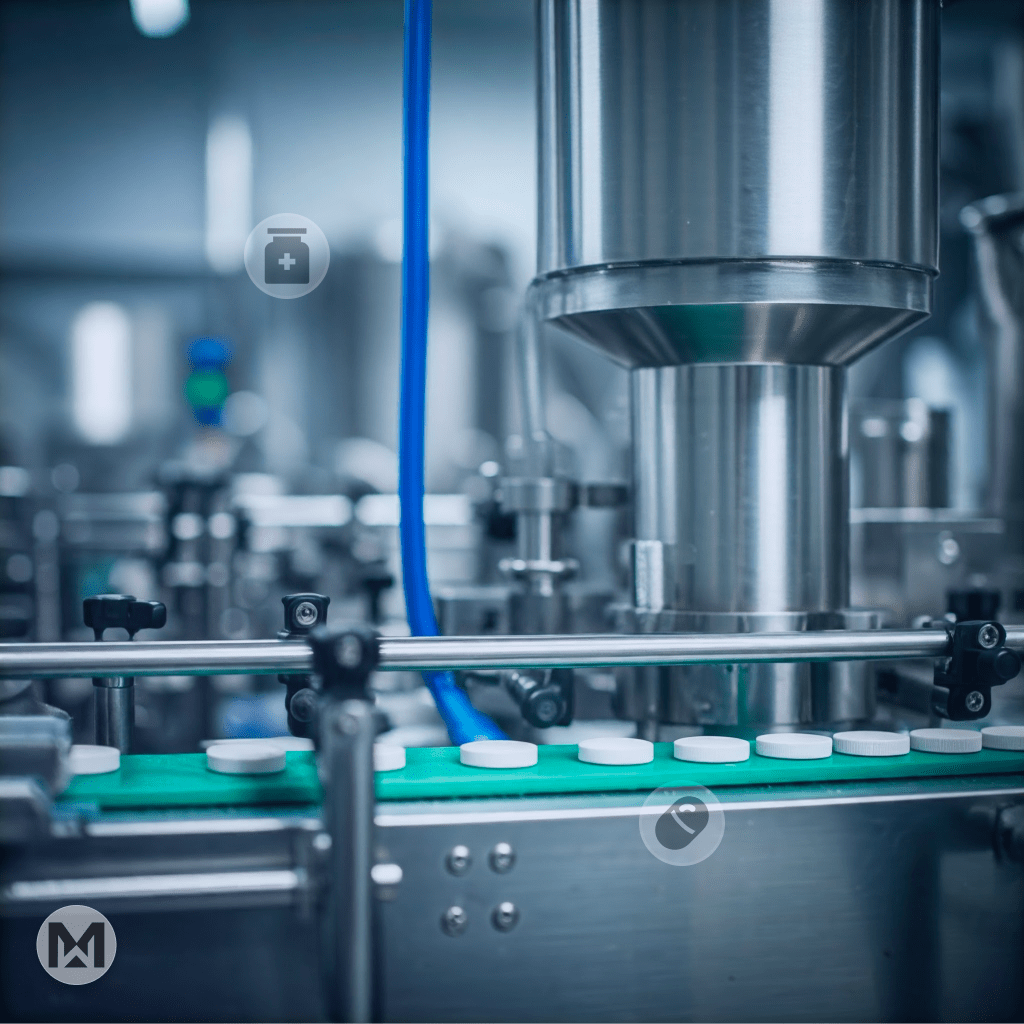

Finishing and Packaging

- Maintain peak efficiency of filling and packaging lines

- Ensure compliance with product labeling equipment

- Optimize performance of quality control instruments

- Minimize downtime in product handling and storage systems

Seamless Integration for Comprehensive Batch Processing Intelligence

MaintWiz AI CMMS offers unparalleled connectivity, integrating with your existing systems to create a unified platform for batch processing excellence and informed decision-making.

Batch Management System (BMS) Integration:

Synchronize maintenance activities with batch schedules, optimizing resource allocation and minimizing production disruptions while ensuring equipment readiness for each batch.

Laboratory Information Management System (LIMS) Connectivity:

Correlate maintenance data with quality control results, enabling rapid identification of equipment-related quality issues and supporting continuous improvement initiatives.

Enterprise Resource Planning (ERP) System Alignment:

Seamlessly integrate maintenance operations with broader business processes, enhancing resource planning, cost tracking, and overall operational efficiency in batch production.

Industrial Internet of Things (IIoT) Platform Synergy:

Harness real-time data from sensors and connected devices to drive predictive maintenance strategies, ensuring optimal performance of critical batch processing equipment.

Optimize Production with MaintWiz AI CMMS to Ensure High Quality, Enhance Reliability, Improve OEE, & Minimize Downtime

Overcoming Batch Processing Challenges with MaintWiz AI CMMS

Address the unique maintenance hurdles in batch manufacturing with our tailored solutions, designed to enhance productivity, quality, and compliance across your operations.

Balancing Flexibility and Standardization in Equipment Maintenance:

MaintWiz's adaptive algorithms optimize maintenance schedules, accommodating diverse batch requirements while maintaining standardized procedures for consistent quality and efficiency.

Minimizing Changeover Times Between Batches:

AI-driven insights optimize equipment cleaning and setup processes, reducing downtime between batches and increasing overall production capacity without compromising quality.

Optimizing Resource Allocation for Variable Batch Sizes:

MaintWiz's intelligent scheduling adapts maintenance activities to fluctuating production demands, ensuring optimal resource utilization across different batch sizes and product types.

Ensuring Batch-to-Batch Consistency Through Equipment Reliability:

Our predictive maintenance capabilities minimize equipment variability, supporting consistent product quality across batches and reducing the risk of costly product rejections.

Managing Complex Regulatory Compliance Requirements:

Automate compliance processes with built-in tools for documentation, audit trails, and regulatory reporting, simplifying adherence to FDA, GMP, and other industry standards.

Enhancing Traceability for Quality Assurance and Recalls:

Comprehensive equipment history and maintenance logs support robust traceability, facilitating rapid root cause analysis and targeted recalls when necessary.

Streamlined Implementation for Rapid ROI in Batch Processing

Experience a smooth transition to enhanced maintenance practices with MaintWiz's tailored implementation process, designed to minimize disruption and maximize value for your batch processing operations.

Customized Batch Processing Asset Mapping:

Our experts conduct a thorough analysis of your batch equipment, creating a detailed digital asset inventory tailored to your specific manufacturing processes.

Seamless Integration with Existing Batch Systems:

MaintWiz's flexible architecture ensures smooth integration with your current batch management and control systems, preserving your existing investments while enhancing capabilities.

Tailored Training for Batch Processing Teams:

Comprehensive training programs equip your maintenance and operations teams with the skills to leverage MaintWiz's full potential in the unique context of batch manufacturing.

Phased Roll-out Minimizing Operational Impact:

Our staged implementation approach allows for gradual adoption, ensuring minimal disruption to your ongoing batch production while steadily improving maintenance practices.

Continuous Optimization for Batch Excellence:

Post-implementation, our team provides ongoing support and fine-tuning, ensuring MaintWiz continues to evolve with your changing batch processing needs and industry trends.

Request a one-one demo with our solution engineering team.

Request a one-one demo with our solution engineering team.