Brewing Excellence: MaintWiz AI CMMS for Breweries & Distilleries

Unlock peak performance and ensure regulatory compliance with MaintWiz AI CMMS. Our intelligent solution optimizes asset management, enhances production efficiency, and maintains product quality for breweries and distilleries of all sizes.

Transformative Benefits of MaintWiz AI CMMS for Breweries and Distilleries

Crafting Success: MaintWiz AI CMMS Benefits for Breweries and Distilleries

Harness the power of AI to forecast equipment failures and optimize maintenance schedules, ensuring uninterrupted production flows.

Maximize Equipment Uptime and Reliability:

Implement predictive maintenance strategies to reduce unexpected breakdowns and optimize production schedules. Our AI-driven insights help you anticipate issues before they impact your brewing process.

Ensure Consistent Product Quality:

Maintain precise control over critical equipment parameters to guarantee consistent flavor profiles and product standards. MaintWiz helps you adhere to strict quality control measures throughout the production cycle.

Streamline Compliance and Documentation:

Effortlessly manage regulatory requirements with automated record-keeping and reporting. Stay audit-ready and maintain compliance with food safety standards like HACCP and FDA regulations.

Optimize Resource Allocation:

Intelligently allocate maintenance resources based on equipment criticality and production demands. Minimize downtime during peak seasons and ensure efficient use of your skilled workforce.

Enhance Energy Efficiency:

Monitor and optimize energy consumption across your facility. MaintWiz helps identify inefficiencies in utilities usage, reducing operational costs and supporting sustainability initiatives in your brewing operations.

Top Companies in India & Abroad Trust MaintWiz CMMS

Speak to a Specialist

Get personalised advice from our experts

Why MaintWiz AI CMMS is the Perfect Blend for Your Brewery

Discover how MaintWiz AI CMMS addresses the unique challenges of the brewing and distilling industry, providing a tailored solution that grows with your business.

Comprehensive Coverage: MaintWiz AI CMMS Across Your Brewery

Experience seamless maintenance management throughout your entire brewing process with MaintWiz AI CMMS, ensuring optimal performance at every stage of production.

Brewhouse Operations:

- Optimize mashing and lautering equipment maintenance schedules

- Monitor and maintain precise temperature control systems

- Ensure timely cleaning and sanitation of kettles and whirlpools

- Track wear and tear on pumps and valves for proactive replacement

Fermentation and Conditioning:

- Maintain optimal performance of fermentation tanks and cooling systems

- Schedule regular integrity checks for pressure vessels and safety valves

- Monitor and maintain yeast propagation equipment efficiently

- Ensure proper functioning of CO2 recovery systems

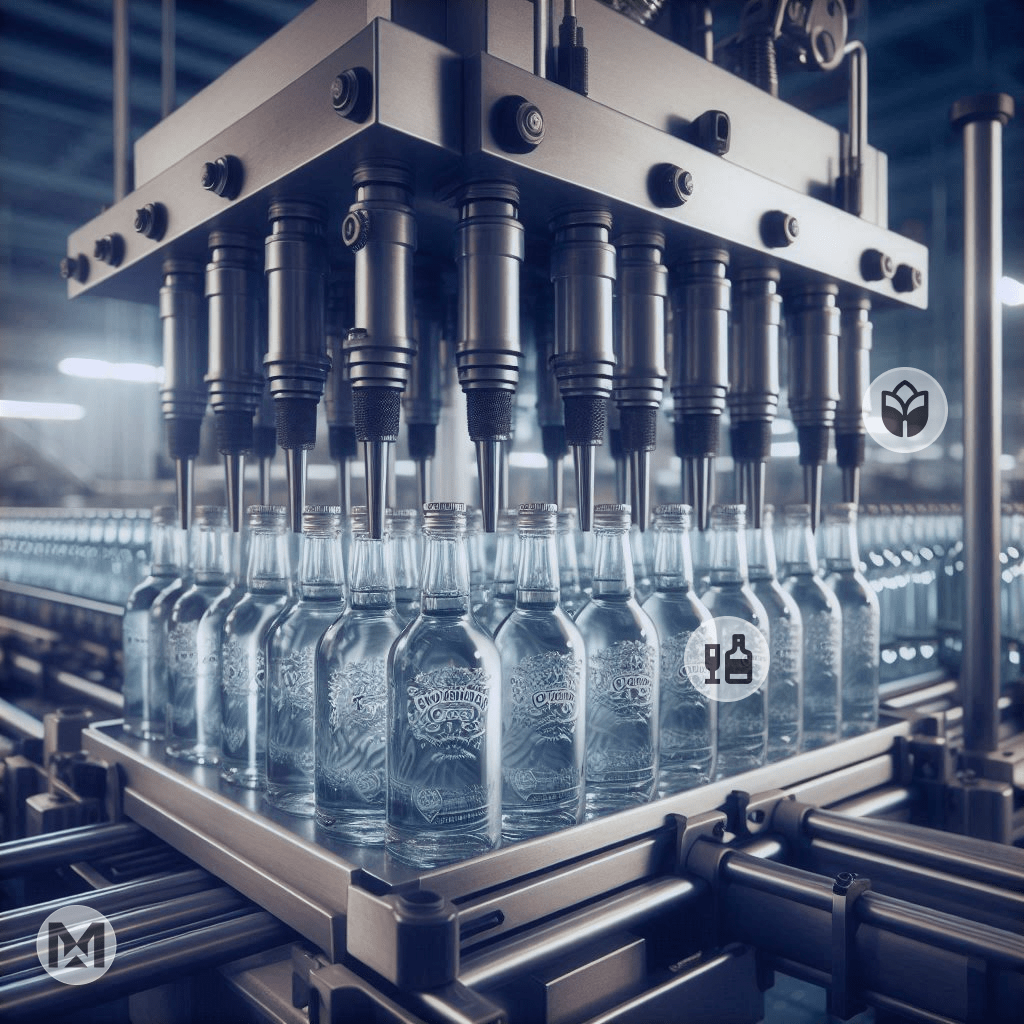

Packaging and Bottling:

- Streamline maintenance for filling lines and conveyor systems

- Optimize performance of labeling and coding equipment

- Ensure regular calibration of weighing and measuring instruments

- Maintain efficient operation of keg washing and filling stations

Utilities and Support Systems:

- Monitor and maintain critical HVAC and refrigeration systems

- Optimize performance of water treatment and steam generation plants

- Ensure reliability of electrical distribution and backup power systems

- Maintain efficient operation of compressed air and gas systems

Seamless Integration: Enhancing Your Brewery's Ecosystem

MaintWiz AI CMMS integrates effortlessly with your existing systems, creating a unified platform for comprehensive brewery management and intelligence.

ERP and Production Planning Integration:

Synchronize maintenance schedules with production plans to minimize disruptions and optimize resource allocation across your brewing operations.

Quality Management System (QMS) Connectivity:

Integrate with your QMS to ensure maintenance activities align with quality control processes, maintaining consistent product excellence throughout production.

IoT and Sensor Data Incorporation:

Harness real-time data from brewing equipment sensors to enable predictive maintenance and optimize performance across your entire production line.

Automated Work Order Generation:

Leverage AI to automatically create and prioritize work orders based on equipment conditions, production schedules, and compliance requirements.

Optimize Production with MaintWiz AI CMMS to Ensure High Quality, Enhance Reliability, Improve OEE, and Minimize Downtime

Addressing Key Challenges in Brewery Maintenance and Operations

MaintWiz AI CMMS tackles the unique challenges faced by breweries and distilleries, ensuring smooth operations, quality consistency, and regulatory compliance.

Balancing Preventive Maintenance with Production Demands:

Optimize maintenance schedules to minimize downtime during peak production periods while ensuring equipment reliability and product quality.

Managing Seasonal Production Fluctuations:

Adapt maintenance strategies to accommodate seasonal brewing demands, ensuring equipment readiness during high-volume periods.

Maintaining Consistent Product Quality:

Ensure precise control of brewing parameters through regular equipment calibration and maintenance, guaranteeing consistent flavor profiles.

Ensuring Strict Hygiene and Sanitation Standards:

Maintain rigorous cleaning and sanitization schedules for all equipment, adhering to food safety regulations and preserving product integrity.

Controlling Energy Consumption and Sustainability:

Monitor and optimize energy usage across brewing processes, supporting sustainability initiatives and reducing operational costs.

Compliance with Evolving Regulatory Requirements:

Stay ahead of changing regulations with automated documentation and reporting features, ensuring compliance with industry standards and local laws.

Implementing MaintWiz AI CMMS: A Recipe for Success

Embark on a seamless journey to optimize your brewery's maintenance operations with our tailored implementation process.

Customized Needs Assessment and Planning:

We analyze your unique brewing processes and equipment to create a tailored implementation strategy that aligns with your operational goals.

Seamless Data Migration and System Integration:

Our experts ensure smooth transfer of existing maintenance data and seamless integration with your current brewery management systems.

Comprehensive Training and Onboarding:

We provide thorough training for your team, ensuring they can leverage MaintWiz's full potential to enhance brewery operations and maintenance efficiency.

Ongoing Support and Continuous Improvement:

Our dedicated support team assists you post-implementation, offering regular system updates and optimization suggestions to maximize your CMMS investment.

Request a one-one demo with our solution engineering team.

Request a one-one demo with our solution engineering team.