The Most Controversial TPM Debate in Maintenance Today (And Where You Should Stand)

For decades, Total Productive Maintenance (TPM) has been positioned as the gold standard for industrial reliability. Posters celebrate zero breakdowns. Dashboards track preventive maintenance (PM) compliance. Plants proudly report thousands of maintenance tasks executed on time.

And yet—across manufacturing, energy, utilities, and process industries—leaders are facing an uncomfortable paradox:

Maintenance spend is rising.

PM compliance is improving.

But reliability is flat—or worse, declining.

This contradiction has ignited one of the most controversial debates in modern maintenance leadership:

Is TPM still delivering reliability—or has it devolved into a volume-driven activity system that actively creates failure?

This article explores that debate deeply—not from theory, but through reliability science, real plant behavior, and observed data across asset-intensive organizations. Most importantly, it explains how modern CMMS platforms like MaintWiz reshape TPM into a precision system, not a blunt instrument.

The Original Promise of TPM—and Where It Quietly Drifted

What TPM Was Meant to Achieve

TPM was never about “doing more maintenance.”

Its original intent was strategic and disciplined:

- Eliminate breakdowns through early loss detection

- Shift maintenance from reactive firefighting to proactive control

- Embed ownership at the operator level

- Improve Overall Equipment Effectiveness (OEE) holistically

In practice, however, TPM implementation often drifted into maintenance volume maximization.

How TPM Drifted from Strategy to Activity

Common global patterns include:

- PM task lists expand — but are rarely pruned

- Inspection frequencies increase — but failure rates don’t fall

- Compliance becomes a KPI — while failure elimination is ignored

- Success is measured by work orders closed, not failures prevented

Keyword insight: TPM execution vs TPM outcomes

👉 TPM did not fail. Execution frameworks failed to evolve.

The Core TPM Controversy: Does More Maintenance Increase Failure Risk?

The Counterintuitive Reality

Reliability engineering has long established a principle many TPM programs ignore:

Every maintenance intervention introduces risk.

This reality sits at the heart of the TPM debate.

Why Excessive Maintenance Becomes a Failure Mode

- Maintenance-Induced Failures

- Reassembly errors

- Incorrect torque

- Contamination

- Misalignment

- Infant Mortality After Maintenance

- Failure probability often spikes immediately after intervention

- Especially in rotating and electrical assets

- Human Error Amplification

- Overloaded schedules increase cognitive fatigue

- Procedural shortcuts become statistically inevitable

Keyword insight: Maintenance-induced failure risk

👉 When TPM emphasizes task volume over failure relevance, reliability degrades.

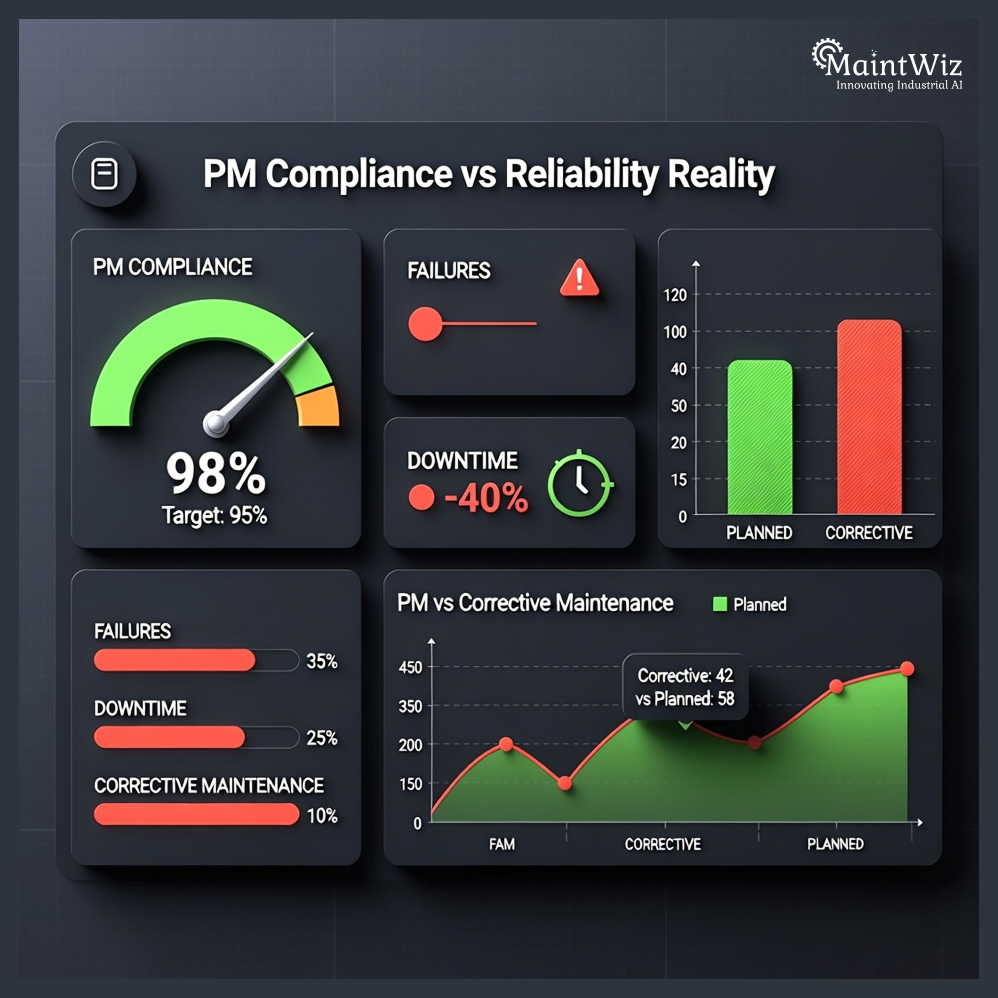

Preventive Maintenance Compliance: The Most Misleading KPI in TPM

Why “Green Dashboards” Can Be Dangerous

Many plants proudly report:

- 95–100% PM compliance

- Thousands of completed work orders

Yet simultaneously experience:

- Recurring failures

- Rising corrective maintenance

- Unplanned downtime

Why PM Compliance Fails as a Reliability Indicator

- Compliance Measures Activity—Not Value

- No link to dominant failure modes

- No validation of risk reduction

- High Compliance Can Mask Poor Strategy

- Tasks persist long after relevance disappears

- “No fault found” work orders increase

- Compliance Incentivizes Over-Maintenance

Teams are rewarded for doing—not thinking

Keyword insight: PM compliance vs reliability outcomes

👉 TPM fails when measurement rewards motion, not impact.

The Hidden Cost Curve of TPM Overreach

TPM as a Cost Multiplier

When TPM becomes overextended, costs compound silently across the enterprise.

Where the Real Costs Appear

- Direct Costs

- Labor hours

- Spare parts

- Contractor reliance

- Opportunity Costs

- Planned downtime reduces throughput

- Engineering time diverted from improvement

- Data Distortion Costs

- MTBF becomes unreliable

- Condition baselines lose meaning

Keyword insight: Over-maintenance cost curve

👉 Ironically, TPM—designed to reduce waste—can become one of the largest sources of it.

The Real Issue: TPM Without Failure Intelligence

Why Traditional TPM Lacks Precision

Classic TPM frameworks evolved before:

- High-resolution asset data

- Automated failure capture

- AI-assisted pattern detection

As a result, TPM often operates blind to real failure behavior.

What’s Missing in Traditional TPM

- Failure Mode Visibility

- Tasks not mapped to actual degradation mechanisms

- Closed-Loop Learning

- Failures don’t automatically update PM strategies

- Dynamic Prioritization

- Critical assets treated the same as low-risk ones

Keyword insight: Failure-driven maintenance strategy

👉 TPM without intelligence becomes ritual—not reliability.

The Modern TPM Reset: From Volume to Precision

How Leading Plants Are Rewriting TPM

World-class organizations are not abandoning TPM.

They are re-architecting it around data, risk, and learning loops.

What Modern TPM Looks Like

- Failure-Mode-Aligned Maintenance

- Tasks exist only where they mitigate known risks

- Condition-Based Intervention

- Time-based PM replaced by evidence-based triggers

- Asset Criticality Weighting

- 20% of assets receive 80% of attention

Keyword insight: Risk-based TPM execution

👉 This evolution requires a fundamentally different digital backbone.

Why CMMS Is the Deciding Factor in the TPM Debate

TPM Is a System Problem—Not a Behavior Problem

TPM success is constrained by the system supporting it.

Legacy CMMS platforms were designed to:

- Schedule tasks

- Close work orders

- Track compliance

👉 They were not designed to think.

What a Modern CMMS Must Enable

- Failure-Centric Data Models

- Assets, failures, causes, actions structurally linked

- Dynamic PM Optimization

- Tasks added, modified, or eliminated based on evidence

- Execution-to-Outcome Traceability

- Can we prove this task prevented this failure?

Keyword insight: Intelligent CMMS for TPM

👉 This is where the debate decisively shifts.

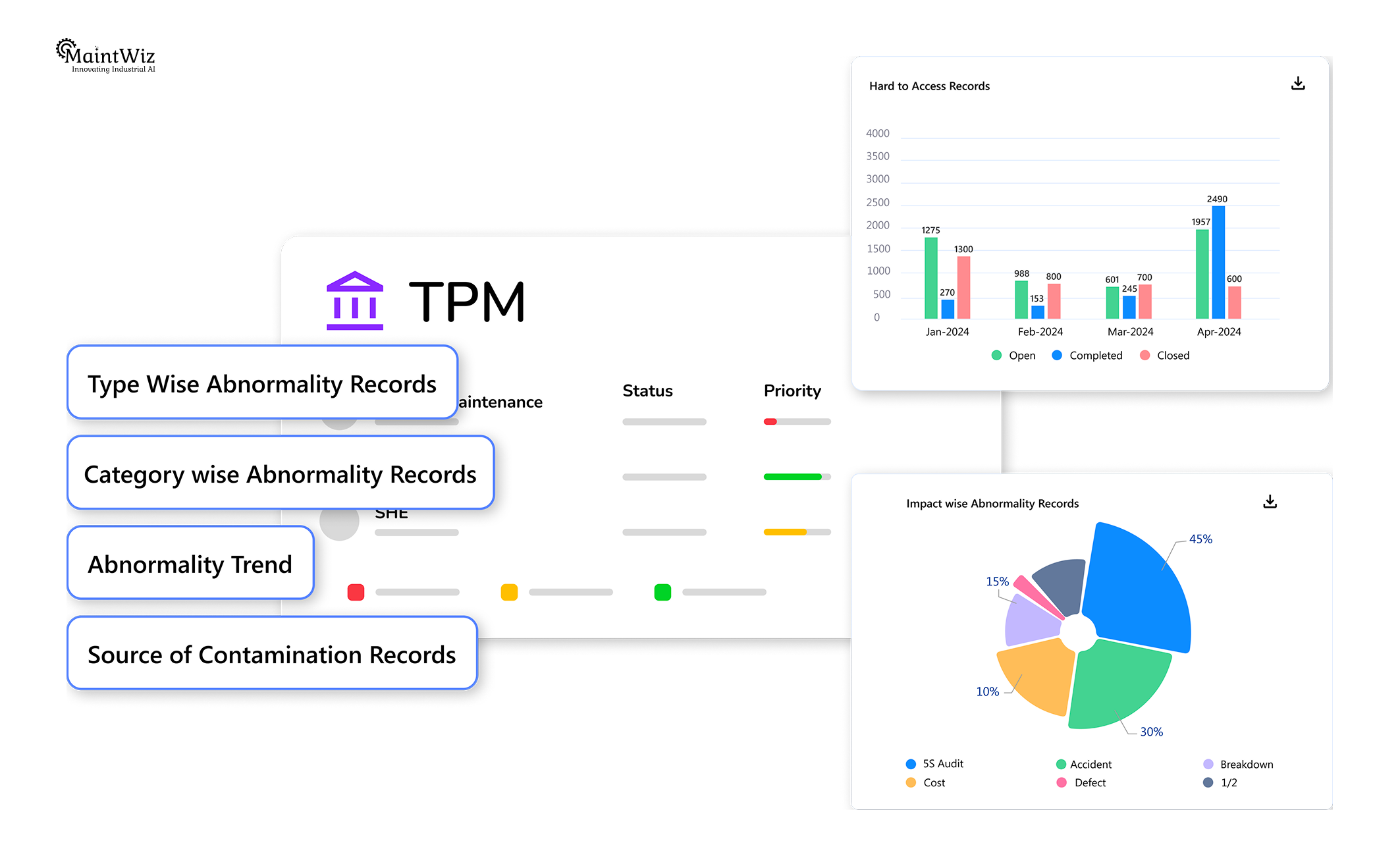

Why MaintWiz CMMS Changes the TPM Equation Entirely

TPM Finally Aligned with Reliability Science

MaintWiz CMMS is built on one core principle:

Maintenance should exist only to eliminate failure risk—not to satisfy schedules.

How MaintWiz Redefines TPM Execution

- Failure Intelligence Built In

- Native root cause tracking

- Failure pattern recognition

- Cause-to-action traceability

- Adaptive Preventive Maintenance

- PM frequencies evolve automatically

- Low-value tasks are identified and retired

- Asset Criticality–Driven Focus

- Maintenance aligns with business risk

- TPM becomes selective, not universal

- Closed-Loop Reliability Learning

- Every failure improves the system

- TPM matures continuously—not annually

Keyword insight: AI-driven TPM optimization

👉 MaintWiz does not automate maintenance volume.

👉 It optimizes maintenance relevance.

The Future of TPM: Doing Less—Far Better

The Leadership Shift Required

The TPM debate is not technical.

It is philosophical.

Leaders must choose between:

- Comfort in activity

- Discipline in effectiveness

What High-Performance Organizations Embrace

- Fewer tasks

- Smarter triggers

- Stronger accountability

- Measurable failure reduction

Keyword insight: Outcome-driven maintenance leadership

Final Thought

TPM is not dead.

But blind TPM must be retired.

With platforms like MaintWiz CMMS, TPM finally becomes what it was always meant to be:

A system that prevents failure—not one that produces work.

Jai Balachandran is an industry expert with a proven track record in driving digital transformation and Industry 4.0 technologies. With a rich background in asset management, plant maintenance, connected systems, TPM and reliability initiatives, he brings unparalleled insight and delivery excellence to Plant Operations.