We Optimized Everything — Except the One Thing That Matters

Most industrial plants proudly share optimized dashboards, meticulous PM schedules, and stacked compliance checklists. Yet, unplanned downtime still knocks at the worst possible times. What if all that optimization was missing the single most impactful element — the quality of decisions that drive reliability, resource allocation, and asset performance?

The answer reshapes how maintenance transforms from cost center to strategic advantage.

In this post, we explore how traditional optimization falls short, why strategic decision frameworks are more impactful than metrics alone, and how Modern AI-enabled CMMS platforms like MaintWiz finally bridge the execution gap, making maintenance predictive, proactive, and aligned with organizational goals.

Why Traditional Maintenance Optimization Often Fails

Overview:

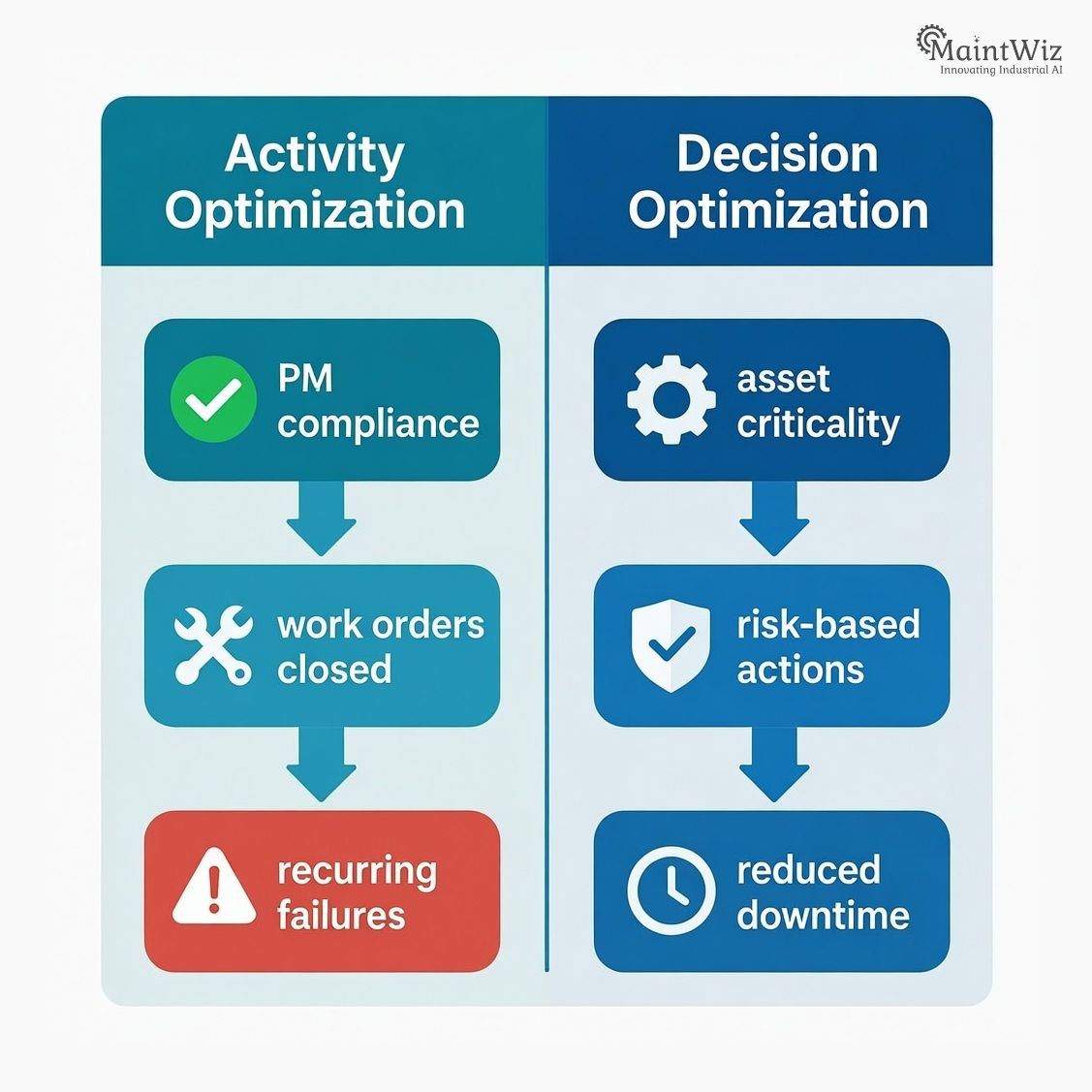

Many maintenance improvement initiatives focus on activity metrics — number of PMs completed, work orders closed, or compliance percentages. While these are valuable indicators, they rarely capture the impact of maintenance decisions on asset reliability and long-term performance.

- Measurement Doesn’t Equal Impact

- Optimized metrics, minimal results: You might have 98% compliance with PM schedules, but if those PMs aren’t preventing failures, the metric masks inefficiency.

- Activity vs outcome: Tracking work order counts doesn’t reveal whether the right maintenance actions were taken at the right time.

- System Siloes Hinder Decision Clarity

- Fragmented information: Maintenance data often lives in disparate systems, spreadsheets, or paper logs, making holistic decisions difficult.

- Lack of centralized insights: Without unified asset intelligence, leaders can’t prioritize actions based on risk or strategic value.

- Reactive Culture Outweighs Proactive Strategy

- Firefighting as default: Reactive breakdowns interrupt planned work because teams lack foresight tools.

- Habit over insight: Technicians and planners follow schedules but may not have decision frameworks to handle exceptions.

This gap — between optimized execution and strategic decision-making — is where most maintenance programs plateau. To break through, organizations need systems that encourage the right decisions, not just track activities.

The New Frontier: Strategic Decision-Centric Maintenance

Overview:

Transitioning from activity optimization to decision optimization shifts focus from “how much work we did” to “how impactful the work was.” This shift unlocks real gains in uptime, cost avoidance, resource allocation, and equipment reliability.

- Prioritized Work Based on Asset Criticality

- Impact-driven planning: Not all assets are equal — prioritize maintenance on assets with highest failure consequences.

- Risk alignment: Decision logic embeds asset criticality into scheduling and work order generation.

- Data-Enriched Decision Frameworks

- Centralized intelligence: A unified CMMS platform ensures all asset data — from performance history to sensor signals — drives decision logic.

- Trend insights over snapshot views: Seeing how asset behavior evolves enables better resource allocation.

- Real-Time Decisions at the Point of Work

- Mobile context: Technicians get actionable recommendations at the point of execution, not after a review meeting.

- Reduced delays: Real-time alerts and workflows minimize bottlenecks and keep tasks aligned with priority.

By shifting to decision frameworks powered by real insights, maintenance teams move from routine execution to strategic operations.

How Modern CMMS Makes Decisions the Center of Maintenance Strategy

Overview:

A Computerized Maintenance Management System (CMMS) can no longer be a digital filing cabinet. The most effective systems now embed guidance, priorities, and AI-augmented logic directly into daily maintenance workflows.

- Intelligent Work Order Prioritization

- AI-driven triggers: Shape work orders not just by schedule, but by predictive signals and asset performance trends.

- Contextual understanding: Prioritize tasks based on interconnected data — not siloed calendars.

- Unified Asset Lifecycle Visibility

- Single asset source: Centralized histories give a holistic view of asset health, maintenance history, and risk exposure.

- Better CAPEX decisions: Leaders can make more informed replacement vs repair decisions with complete lifecycle data.

- Integrated Predictive Maintenance Insights

- Early warnings: Predictive capabilities surface patterns that human planners may miss, enabling proactive interventions.

- Reduced emergency repairs: With insights from data trends, teams can schedule work before assets fail unexpectedly.

- Seamless ERP, OT & IoT Integration

- Connected systems: Eliminates manual data reconciliation and provides a single pane of truth for asset performance.

- Real-time feedback loops: Sensor data and operational metrics inform maintenance decisions continuously.

These capabilities move maintenance from tracking tasks to informing actions that meaningfully impact uptime, cost, and safety.

Leadership Actions That Transform Maintenance Culture

Overview:

Organizations that benefit most from modern maintenance strategies invest not just in tools, but in leadership practices that reinforce data-driven decisions and continuous improvement.

- Align Leadership Metrics with Business Outcomes

- Outcome-focused KPIs: Shift evaluation from tasks completed to reliability improvements and cost avoidance.

- Cross-functional goals: Maintenance metrics should align with production, safety, and financial objectives.

- Encourage Data-Backed Decisions

- Accessible dashboards: Leadership must enable frontline users to see and trust data insights.

- Regular reviews: Use trend analytics to inform strategic planning, not just operational reports.

- Empower Teams with Decision Support Tools

- Training & development: Robust competency management ensures teams use tools effectively.

- Mobile access: Provide frontline technicians with contextual insights when and where decisions are made.

By embedding decision frameworks into both tools and culture, plants unlock higher reliability with measurable outcomes.

Why This Matters for Asset Performance and ROI

Overview:

Organizations that focus on strategic decision frameworks see dramatic improvements across key performance dimensions. Rather than optimizing metrics in isolation, they optimize for lasting impact.

- Reduced Downtime and Failure Rates

- Fewer surprises: Predictive insights and prioritized maintenance keep assets running longer.

- Proactive interventions: Strategic decision cues reduce emergency work orders and reactive fixes.

- Extended Asset Lifespan

- Preventive focus: Long-term reliability improves when assets receive maintenance based on performance patterns.

- Lifecycle planning: Complete visibility enables strategic replacement planning.

- Improved Resource Utilization

- Optimized staffing: Teams work on the most impactful tasks.

- Efficient inventory: Parts match prioritized maintenance needs, reducing spares waste.

- Better Financial Outcomes

- Lower maintenance costs: Proactive strategies minimize expensive breakdowns and expedite repairs.

- Strategic CAPEX decisions: Data-backed insights inform replacement investments.

In short, the shift from activity to decisions transforms maintenance from a cost center into a value driver.

Why MaintWiz CMMS Is the Strategic Engine Modern Plants Need

Overview:

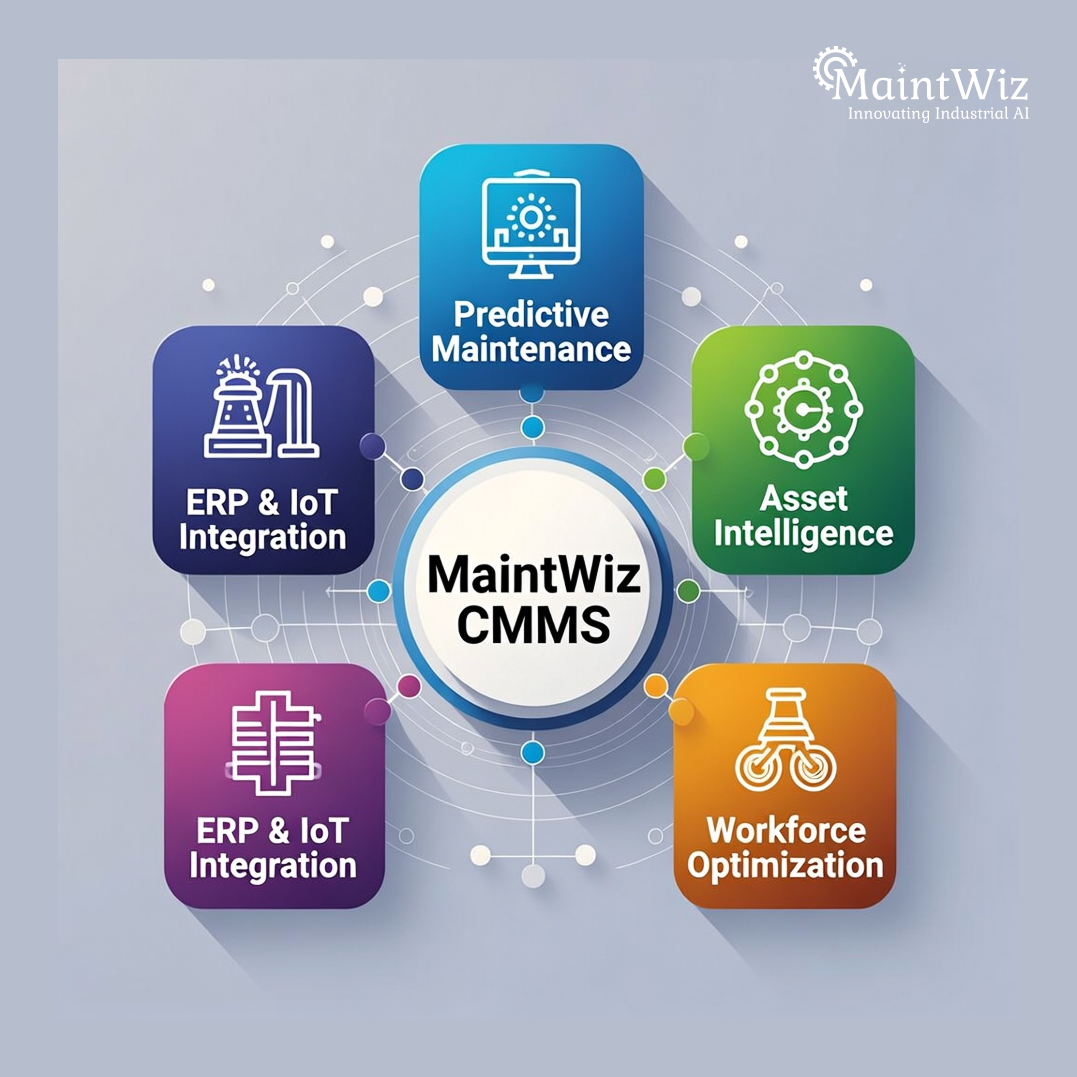

MaintWiz represents the next evolution of CMMS platforms — one that embeds strategic decision support, real-time insights, predictive analytics, and AI-driven workflows into every aspect of maintenance management. Rather than amplifying activity metrics, MaintWiz helps teams make decisions that matter.

- Comprehensive Asset Intelligence

MaintWiz provides a unified view of asset performance, historical maintenance, and future conditions — not just siloed activity logs. This holistic asset monitoring ensures decision logic is grounded in full context.

- Predictive and Condition-Based Maintenance

With AI-powered predictive capabilities, MaintWiz identifies patterns and proposes maintenance actions before failures occur — minimizing unplanned downtime and maximizing uptime.

- Integrated Resource & Workforce Optimization

MaintWiz seamlessly aligns asset priorities with workforce competency, task assignment, and scheduling, ensuring the right teams are working on the right tasks at the right time.

- Intelligent Scheduling and Automation

By automating work order generation and integrating predictive insights, MaintWiz ensures schedules are not just filled — they are optimized for impactful actions.

- Scalability and Integration

MaintWiz fits seamlessly into existing enterprise ecosystems, connecting with ERP, OT, and IoT systems to unify maintenance and operational technology landscapes.

- Mobile-Enabled Decision Support

Technicians gain mobile access to work instructions, alerts, and data at the point of execution — enabling real-time decision support rather than delayed office reporting.

- Continuous Improvement Culture

MaintWiz’s advanced analytics, reporting, and insights empower both frontline teams and leadership to identify trends, drive continuous improvement, and align maintenance with long-term business goals.

By equipping organizations with intelligent asset management, predictive insights, and decision-centric workflows, MaintWiz CMMS doesn’t just help teams do more work — it ensures they do the right work at the right time.

Jai Balachandran is an industry expert with a proven track record in driving digital transformation and Industry 4.0 technologies. With a rich background in asset management, plant maintenance, connected systems, TPM and reliability initiatives, he brings unparalleled insight and delivery excellence to Plant Operations.