Maintenance Isn’t a Cost — It’s a Profit Engine

How Smart Asset Management Turns Maintenance into a Competitive Advantage

For decades, industrial maintenance has been discussed in the wrong room, using the wrong language, and evaluated using the wrong metrics.

In boardrooms, maintenance is still framed as overhead.

In budgets, it appears as a cost to be controlled.

In reviews, success is defined by how little was spent.

And yet, when we study top-quartile manufacturing and process plants globally, a striking pattern emerges:

The most profitable plants are not those that spend the least on maintenance — they are those that extract the most value from it.

This article explains why maintenance is fundamentally a profit engine, how world-class organizations operationalize this thinking, and why modern, intelligence-driven CMMS platforms like MaintWiz CMMS are becoming essential to this transformation.

The Great Misclassification: Why Maintenance Became a “Cost Center”

Overview

Maintenance earned its reputation as a cost center not because it lacks value, but because its value is structurally invisible in traditional management systems.

Key Reasons Maintenance Was Misunderstood

- Indirect Value Creation

Maintenance prevents losses rather than generating invoices. Prevented failures do not appear on income statements. - Success Is the Absence of Events

When machines run smoothly, maintenance success is silent. Failures get noticed; reliability rarely does. - Fragmented Ownership of Benefits

Maintenance benefits production, quality, safety, energy efficiency, and finance—yet no single function “owns” the gain. - Accounting Bias Toward Expense Reduction

Financial systems reward cost cutting more visibly than risk reduction or uptime protection. - Legacy CMMS Limitations

Traditional CMMS platforms focused on logging work orders, not linking maintenance decisions to business outcomes.

The result?

Maintenance became something to be minimized, not optimized.

Maintenance Economics: Where Profit Is Actually Created

Overview

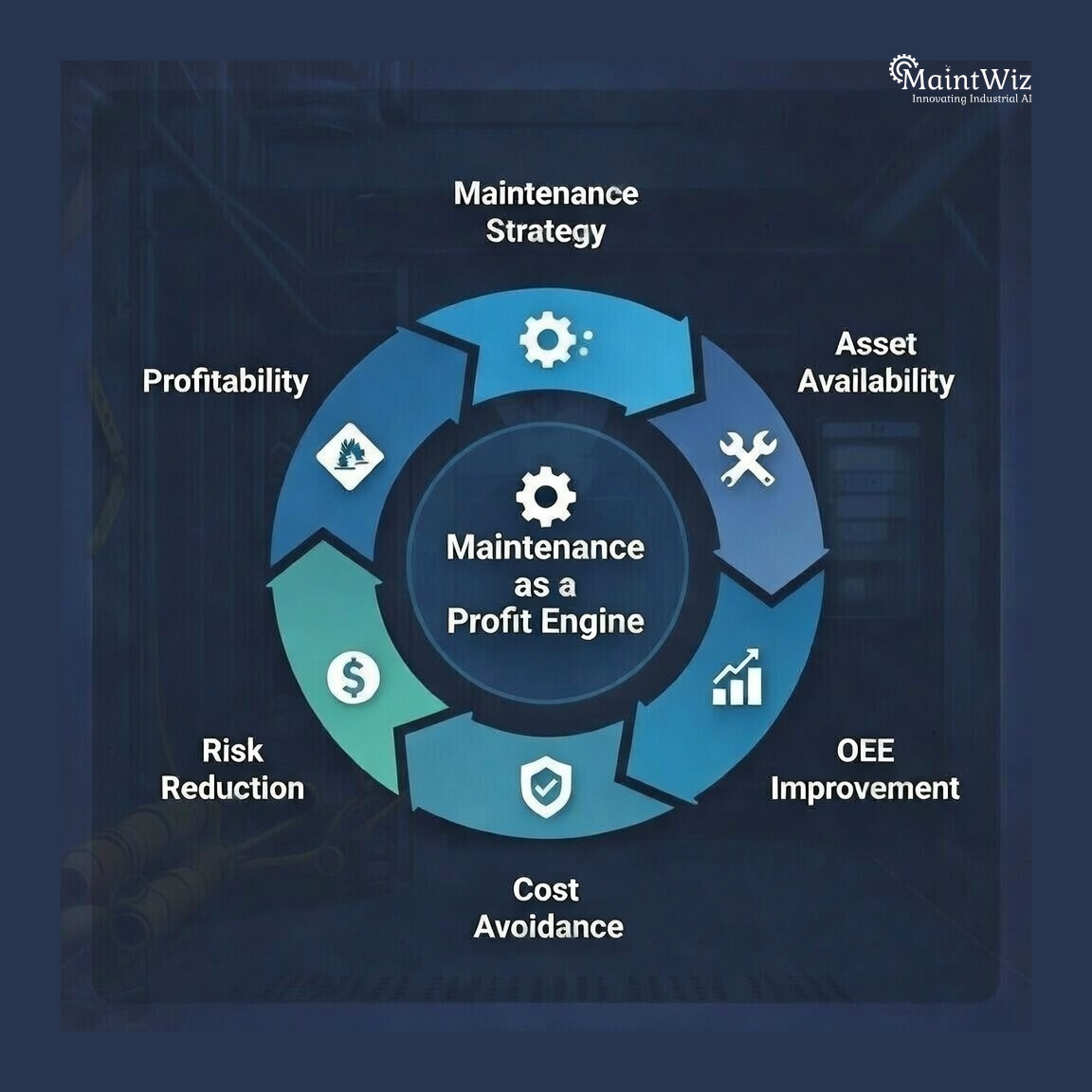

Maintenance directly influences the most powerful financial levers in an industrial operation. These levers determine revenue, margin, capital efficiency, and enterprise risk.

- Asset Availability Drives Revenue

- Every unplanned downtime hour equals lost production

- Lost production cascades into missed deliveries and penalties

- Availability improvement flows directly to top-line revenue

- In continuous industries, 1% availability can equal millions annually

Maintenance is revenue insurance.

- OEE Improvement Unlocks Hidden Capacity

- Availability losses originate from failures

- Performance losses reflect mechanical degradation

- Quality losses often trace back to asset condition

- Better maintenance unlocks 5–15% hidden capacity

- This avoids premature capital expenditure

Reliability is capital efficiency.

- Cost Avoidance Beats Cost Reduction

- Emergency work costs 3–7× planned maintenance

- Secondary damage multiplies repair expense

- Overtime, expediting, and firefighting inflate costs

- Predictive and risk-based maintenance avoids these losses

Cutting maintenance spend often increases total cost.

- Risk Reduction Protects Enterprise Value

- Maintenance failures cause safety incidents

- Regulatory violations trigger fines and shutdowns

- Environmental failures damage brand equity

- Insurance premiums rise with asset risk

Maintenance is enterprise risk management in disguise.

The Maintenance Maturity Curve: Why Most Plants Plateau

Overview

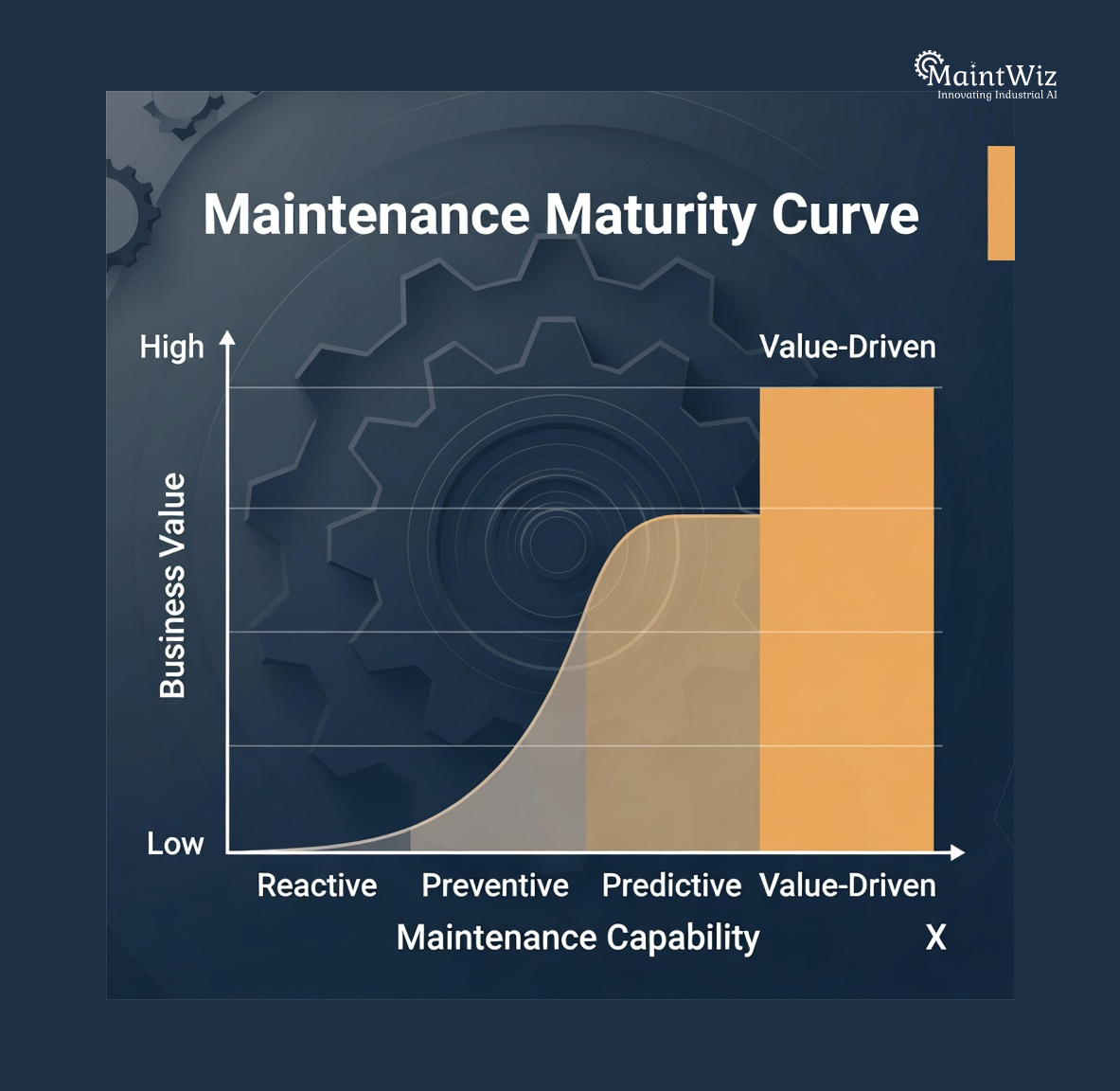

Industrial plants consistently cluster into three maturity levels. Only one of them converts maintenance into profit.

Level 1: Reactive / Firefighting Maintenance

- Breakdowns dictate daily priorities

- PMs exist mainly for audit compliance

- Technicians overloaded with urgent work

- CMMS used as a digital logbook

- Data quality is poor and inconsistent

Outcome: High stress, high cost, low predictability

Level 2: Preventive / Controlled Maintenance

- Preventive maintenance standardized

- Planners and schedulers introduced

- KPIs like MTBF and MTTR tracked

- Limited condition monitoring deployed

Outcome: Stability without optimization

Level 3: Value-Driven / Reliability-Centered Maintenance

- Maintenance strategy aligned to business risk

- Assets prioritized by criticality

- Failures analyzed by financial impact

- Predictive insights guide decisions

- CMMS used as a decision platform

Outcome: Maintenance actively improves profitability

Why “More Maintenance” Is Not Better Maintenance

Overview

One of the most expensive myths in industrial operations is that increasing maintenance activity automatically improves reliability.

The Hidden Cost of Excessive PM

- Over-maintenance increases labor and spares cost

- Human intervention introduces failure risk

- Shutdown windows are consumed inefficiently

- Generic PMs fail to address real failure modes

What High-Performing Plants Do Instead

- Apply risk-based maintenance

- Focus on critical assets

- Eliminate PMs that do not reduce failures

- Continuously refine maintenance strategies

Precision beats volume. Intelligence beats effort.

From Activity Metrics to Outcome Metrics

Overview

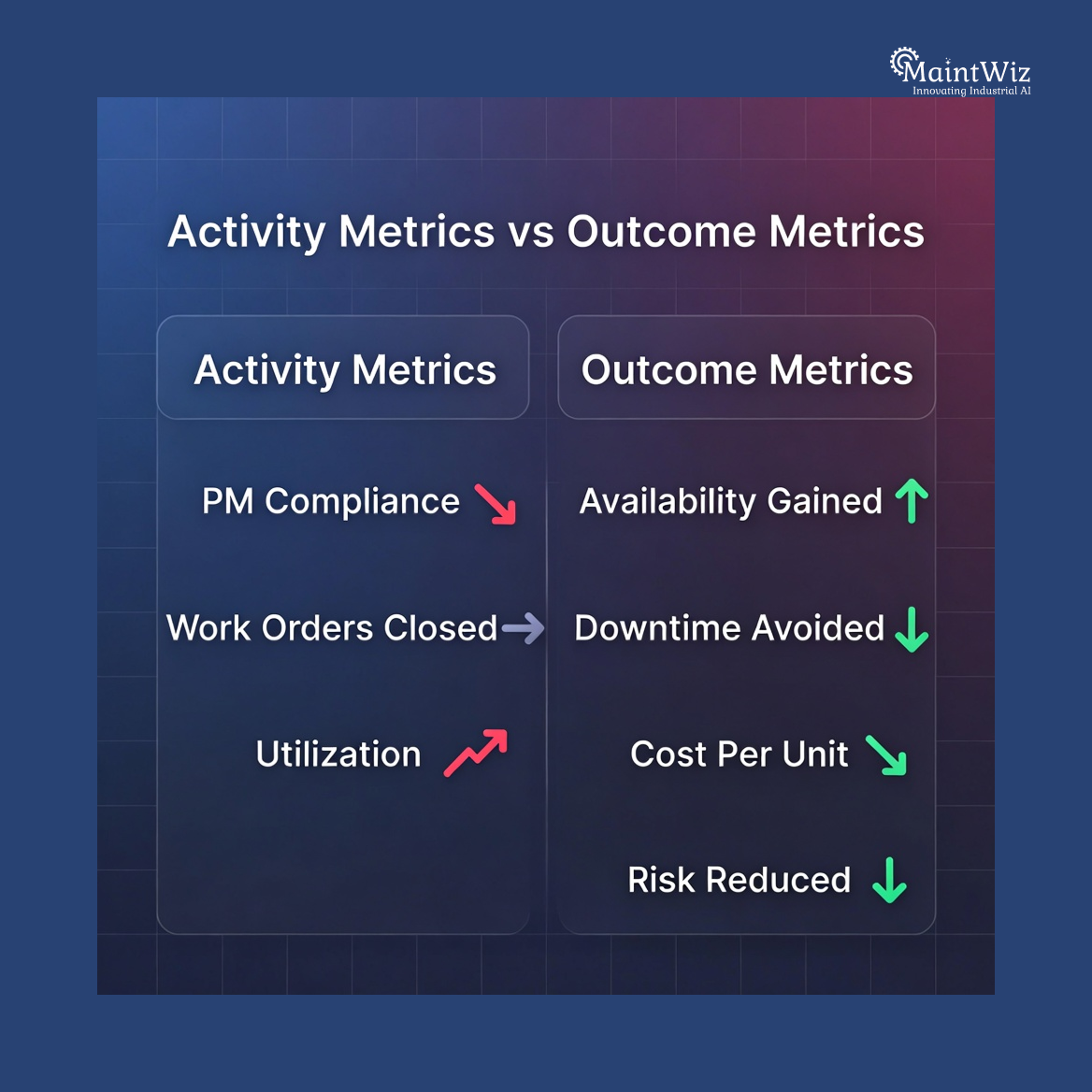

What organizations measure ultimately defines how maintenance behaves.

Legacy Maintenance Metrics (Low Value)

- PM compliance percentage

- Number of work orders closed

- Technician utilization rates

These measure busyness, not effectiveness.

Outcome-Driven Maintenance Metrics (High Value)

- Availability improvement by asset

- Downtime avoided by failure mode

- Maintenance cost per unit of output

- Risk exposure reduced

- Asset life extension achieved

Profit-driven maintenance requires outcome-driven metrics.

The Silent Profit Killer: Poor Maintenance Data

Overview

Many maintenance transformation initiatives fail not because of technology, but because of data integrity issues.

Common Data Failures

- Inconsistent asset hierarchies

- Generic failure codes with no insight

- Copy-pasted PM templates

- No linkage between spares and failures

- Poor downtime root cause capture

Business Impact of Bad Data

- Analytics become unreliable

- Predictive maintenance initiatives stall

- Leadership loses trust in reports

- Decisions revert to intuition

Data quality is the foundation of maintenance intelligence.

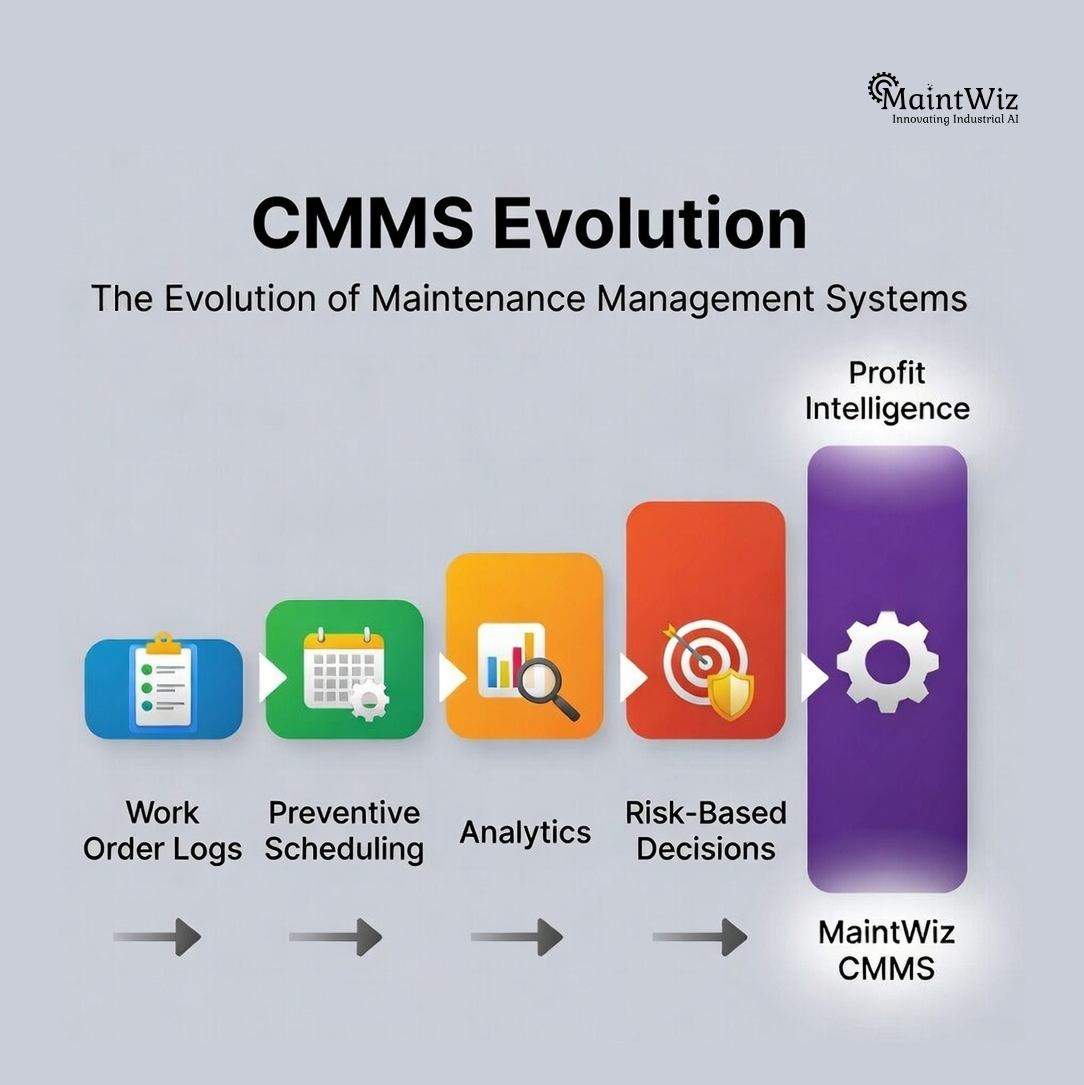

The Evolution of CMMS: From Records to Intelligence

Overview

Modern industrial operations require CMMS platforms to evolve beyond administration into decision enablement.

Traditional CMMS Limitations

- Focused on work order history

- Limited business context

- Reactive reporting

- Little strategic guidance

Modern CMMS Capabilities

- Asset criticality-based prioritization

- Failure mode and downtime analytics

- Predictive insights tied to financial impact

- Spares optimization linked to reliability

- Planner and reliability workflows

- Executive-ready dashboards

CMMS is becoming the nervous system of asset management.

Maintenance as a Leadership and Financial Discipline

Overview

In high-performing organizations, maintenance is no longer confined to the shop floor.

Characteristics of Leadership-Driven Maintenance

- Maintenance discussed at leadership level

- Trade-offs evaluated economically

- Reliability integrated into strategy

- Maintenance leaders speak financial language

- Investment decisions data-driven

Maintenance excellence is a leadership choice.

Why MaintWiz CMMS Is Built for Maintenance as a Profit Engine

Overview

MaintWiz CMMS is designed for organizations that want maintenance to drive business outcomes, not just manage tasks.

How MaintWiz CMMS Enables Profit-Driven Maintenance

- Asset-Centric Architecture

Strong asset hierarchies ensure clean, decision-grade data. - Failure & Downtime Intelligence

Links failures, downtime, and cost to identify profit leaks. - Risk-Based Work Prioritization

Focuses resources on assets that impact revenue and safety most. - PM Optimization Insights

Identifies PMs that add cost without reducing failures. - Spares & Reliability Linkage

Connects inventory behavior to failure patterns. - Predictive & Condition-Based Enablement

Supports transition from reactive to predictive maintenance. - Leadership-Ready Dashboards

Translates maintenance activity into business language.

MaintWiz CMMS does not just help teams do maintenance better.

It helps organizations decide better.

The Bottom Line: Reliability Is the New Profit Strategy

Maintenance is not an unavoidable expense.

It is a controllable, optimizable, and powerful profit lever.

Plants that understand this:

- Run safer operations

- Deliver more consistently

- Spend capital more intelligently

- Outperform competitors structurally

In the next decade, winners will not be defined by who owns the newest assets—but by who extracts the most value from the assets they already have.

Maintenance sits at the center of that equation.

Jai Balachandran is an industry expert with a proven track record in driving digital transformation and Industry 4.0 technologies. With a rich background in asset management, plant maintenance, connected systems, TPM and reliability initiatives, he brings unparalleled insight and delivery excellence to Plant Operations.