Edge AI: Bringing Predictive Intelligence to the Factory Floor — Real-Time, Reliable, and Secure

Introduction: Why Edge AI Is a Game Changer for Modern Maintenance

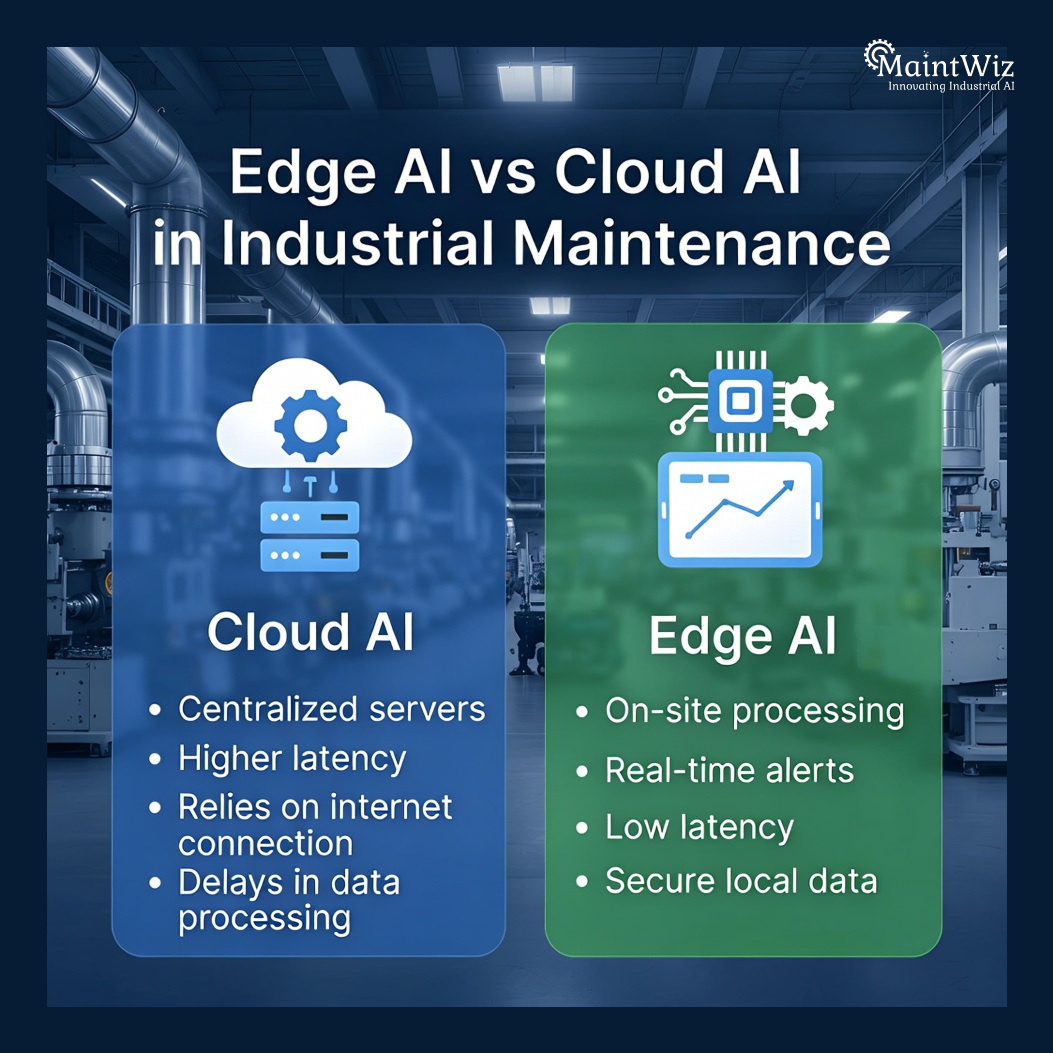

Imagine your factory could predict a machine failure before it happens—not hours later, not days later, but in real time. That future is no longer a distant vision. Edge AI is shifting intelligence from centralized cloud systems directly to the factory floor, enabling predictive insights where it matters most—next to the machines themselves.

Unlike traditional cloud-centric analytics that introduce latency and dependency on network reliability, Edge AI delivers real-time, reliable, and secure insights by processing data locally at the source. For asset-intensive industries, this means faster decisions, reduced downtime, and improved operational resilience. In this article, we explore how Edge AI transforms predictive maintenance and why integrating it with a modern AI CMMS like MaintWiz can revolutionize your maintenance strategy.

What Is Edge AI in Industrial Maintenance?

Overview

Edge AI refers to artificial intelligence that operates at the edge of a network—close to the data source, such as machines and sensors—rather than relying on centralized cloud processing. By processing data locally, Edge AI eliminates the delays and dependency on continuous connectivity that often hinder predictive models in industrial environments.

Key Benefits of Edge AI

- Real-Time Anomaly Detection

Edge AI can spot anomalies and deviations in sensor data instantaneously without waiting for cloud uploads or batch processing. - Reduced Network Dependency

Since insights are generated locally, systems remain functional even during network interruptions. - Enhanced Data Security

Data stays within the plant network, reducing exposure to external threats associated with transmitting data offsite. - Lower Latency for Immediate Action

Faster detection means maintenance teams can respond quickly, reducing unplanned downtime.

By bringing intelligence closer to the machinery, Edge AI ensures that critical insights are not only accurate but also timely, enabling true predictive maintenance.

Why Predictive Maintenance Matters Now More Than Ever

Overview

Predictive maintenance is a strategic shift from reactive (fix after failure) and preventive (scheduled maintenance) approaches to one where insights drive action before a breakdown occurs. With increasing automation and data volumes on production floors, predictive maintenance powered by Edge AI becomes essential for operational excellence.

Key Drivers for Predictive Maintenance

- Minimizing Unplanned Downtime

Predictive models help foresee failures, which can result in up to 30% reduction in unexpected downtime when paired with real-time data monitoring. - Extending Asset Life

Continuous monitoring and early intervention can significantly extend the useful life of expensive equipment. - Optimizing Maintenance Costs

Avoiding unnecessary maintenance and reducing emergency repairs lowers total cost of ownership. - Enhancing Safety and Compliance

Early detection of failures also means mitigating potential safety risks before they escalate. - Boosting Operational Efficiency

Machines that run at optimal performance without frequent breakdowns contribute to better production stability and output.

Predictive maintenance is now a core operational imperative, not a “nice-to-have” feature. Its effectiveness grows exponentially when combined with Edge AI-powered real-time insights.

How Edge AI Enhances Predictive Maintenance

Overview

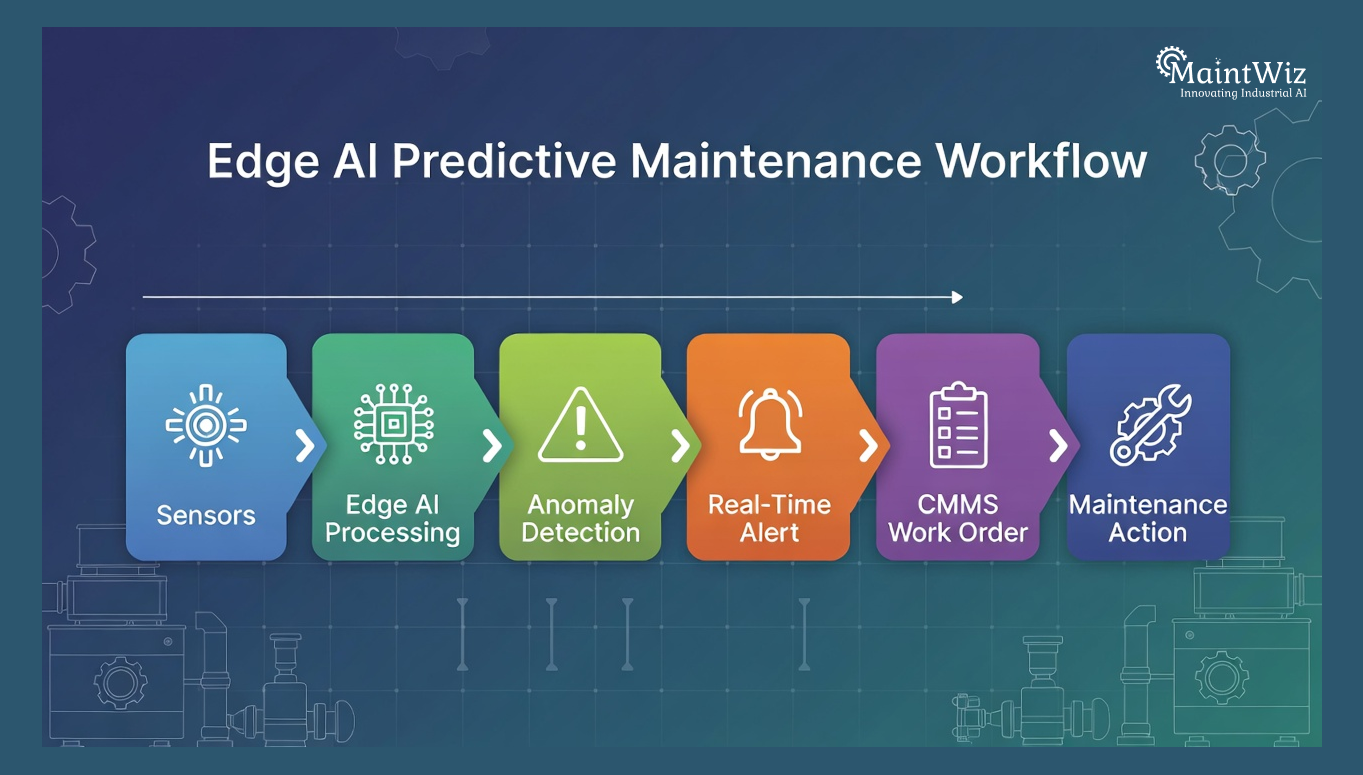

Edge AI transforms predictive maintenance from theoretical value into real operational impact. Instead of waiting for data to travel to the cloud for analysis, models running at the edge can instantly evaluate conditions against anomaly thresholds, health indicators, and failure patterns.

Edge AI Capabilities That Drive Predictive Success

- Local Data Processing for Instant Alerts

Edge AI analysis detects irregularities on-site and triggers alerts without delay. - Hardware State Estimation

Using sensor data like temperature, vibration, and pressure, Edge AI can estimate the health condition of critical components in real time. - Adaptive Models Based on Operational Context

Edge AI can adjust predictive models based on current production cycles and machine conditions. - Reducing False Positives

Local processing helps refine predictions by accounting for machine-specific baselines and environmental variations. - Triggering Automated Actions

Once a potential issue is detected, the system can automatically create or prioritize work orders through integrated maintenance systems.

Edge AI turns raw data into actionable intelligence at the moment it matters, a key enabler of responsive and proactive maintenance workflows.

Integration of Edge AI with Existing Industrial Systems

Overview

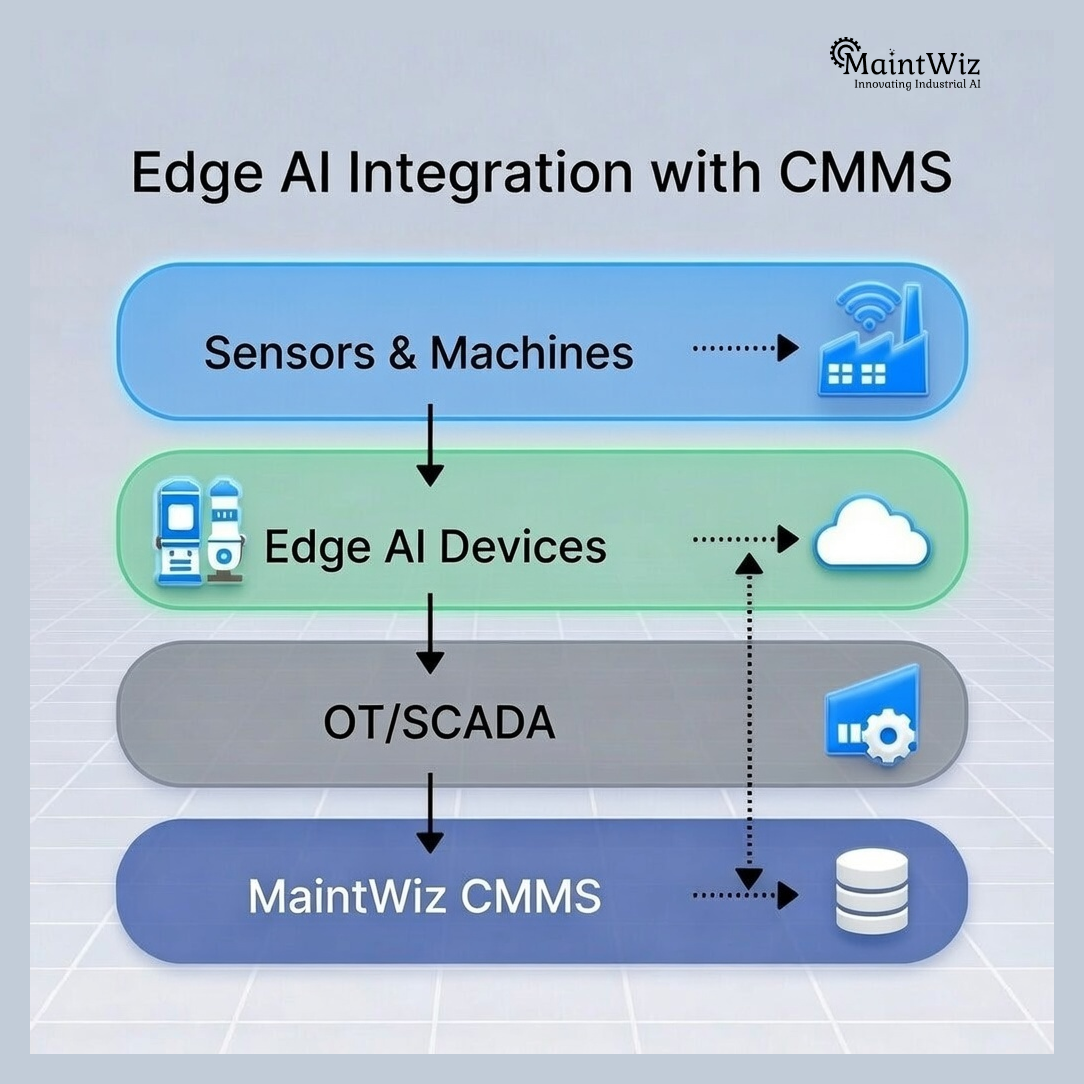

For many manufacturing and industrial facilities, fully modernizing maintenance requires integrating Edge AI with existing infrastructure. This integration includes sensors, OT systems, ERP platforms, and maintenance management tools.

Key Integration Points

- IoT Sensor Networks

Connects vibration, temperature, and flow sensors to Edge AI units for continuous condition monitoring. - Operational Technology (OT) Systems

Integration with SCADA and PLC systems ensures seamless data flow to Edge AI models. - Enterprise Resource Planning (ERP)

Syncing asset master data and maintenance records with ERPs like SAP enhances visibility across departments. - CMMS Integration

Edge AI insights feed directly into CMMS platforms, automating alerts, work orders, and maintenance planning.

Effective integration ensures that Edge AI insights don’t exist in isolation but drive meaningful operational outcomes across the enterprise.

Real-World Industrial Use Cases of Edge AI

Overview

Edge AI’s impact is not hypothetical—it has real, measurable benefits across industries where maintenance reliability directly influences productivity and cost.

High-Impact Use Cases

- Manufacturing Lines

Detect tool wear or vibration anomalies before they lead to production halt. - Heavy Equipment and Motors

Predict motor failure weeks in advance to schedule necessary interventions. - Energy & Utilities

Monitor turbine and generator health continuously and prevent catastrophic failures. - Oil & Gas Facilities

Track pressure fluctuations and corrosion trends that could lead to leaks or hazards. - Process Plants

Ensure continuous operations by spotting early signs of asset degradation.

Across these scenarios, maintenance teams gain visibility and foresight, enabling smarter decision-making and optimized asset performance.

Challenges in Edge AI Adoption and How to Overcome Them

Overview

Despite its power, implementing Edge AI isn’t without challenges. Understanding and addressing these challenges leads to smoother deployment and better outcomes.

Common Challenges and Solutions

- Data Quality and Sensor Calibration

Solution: Standardize sensors, maintain calibration, and ensure clean data input for reliable Edge AI processing. - Legacy Machine Compatibility

Solution: Retrofit sensors and gateways to bring older assets into the connected ecosystem without full equipment replacement. - Integration Complexity

Solution: Use middleware and standardized data protocols to connect OT, Edge AI, and enterprise systems. - Workforce Skills Gap

Solution: Provide targeted training and change management to help teams interpret and act on Edge AI insights. - Cybersecurity Concerns

Solution: Secure edge devices, restrict access, and leverage on-site processing to reduce external vulnerability points.

These challenges are surmountable with careful planning, and the payoff significantly improves reliability and operational resilience.

Edge AI, Predictive Maintenance, and the Role of CMMS

Overview

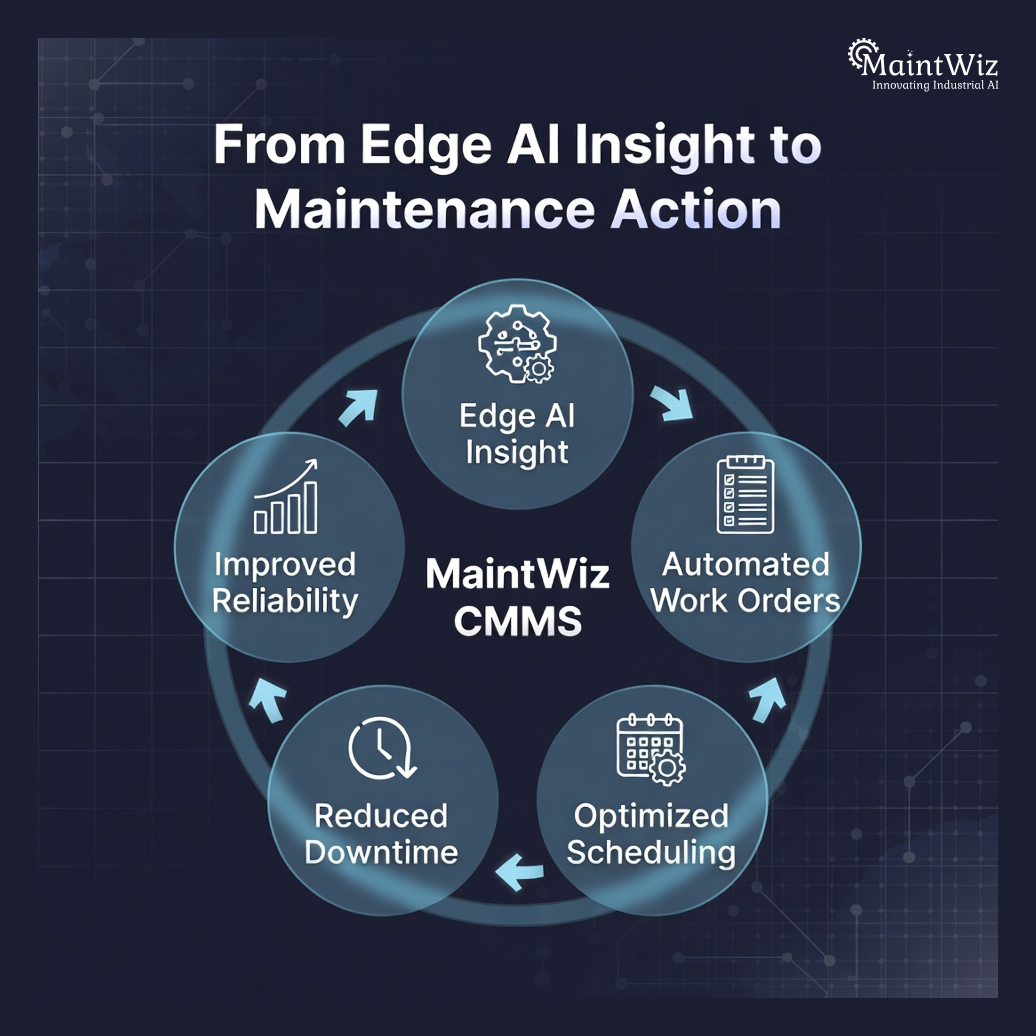

Predictive insights are transformative, but to realize their value, organizations need a system that operationalizes those insights. This is where a modern AI-integrated CMMS becomes critical.

How CMMS Complements Edge AI

- Automated Work Order Generation

Insights from Edge AI trigger work orders automatically, eliminating manual planning. - Maintenance Scheduling Optimization

CMMS platforms adjust maintenance schedules based on real-time health data. - Asset Performance Dashboards

Centralized dashboards combine edge insights with historical maintenance data for deeper analysis. - Mobile Access for On-The-Go Execution

Technicians receive alerts and instructions in real time, empowering faster response and execution. - Inventory and Spare Part Forecasting

Predictive data helps avoid stockouts and optimize spare parts usage.

The synergy between Edge AI and CMMS turns data into actionable maintenance intelligence.

Why MaintWiz CMMS Is the Strategic Choice for Edge AI-Driven Maintenance

Overview

MaintWiz CMMS is more than a maintenance tool—it’s an AI-powered platform designed to harness real-time insights, predictive analytics, and seamless workflow automation to drive maintenance excellence.

Top MaintWiz CMMS Capabilities That Amplify Edge AI Benefits

- AI-Powered Predictive Maintenance

Leveraging advanced machine learning models to forecast equipment failures and optimize maintenance strategies. - Real-Time Asset Condition Monitoring

Integrates with IoT and Edge AI systems to provide continuous health metrics and alerts. - Unified Asset Intelligence Hub

Centralizes real-time operational data with maintenance history and performance metrics. - Automated Work Order & Scheduling

Automatically generates and prioritizes maintenance tasks based on predictive insights and live conditions. - Mobile Maintenance Execution

Supports technicians with on-the-go access to alerts, instructions, and live updates from the factory floor. - Seamless Integration with OT and ERP

Bridges real-time operations with enterprise systems for unified visibility and planning. - Inventory Optimization with AI

Predictive analysis aligns spare parts inventory with maintenance needs to reduce carrying costs. - Digital Twin and Simulation Capabilities

Enables virtual maintenance planning to test strategies without operational risk. - Enhanced Compliance and Documentation

Maintains audit trails and supports industry best practices for regulatory compliance. - Scalable, Enterprise-Ready Platform

Designed to grow with your organization and support complex maintenance environments.

With MaintWiz, organizations can transform real-time predictive data into measurable maintenance performance improvements—a core tenet of Industry 4.0.

Conclusion: The Road Ahead

Edge AI isn’t just another buzzword—it’s a strategic enabler of predictive, proactive maintenance that reduces unplanned downtime, enhances reliability, and drives operational excellence. But real-time intelligence is only part of the equation. The true differentiator lies in how these insights are operationalized—and that’s where leading CMMS platforms like MaintWiz bring transformative value.

By combining Edge AI’s real-time predictive capabilities with a comprehensive AI CMMS, organizations unlock a maintenance ecosystem that is not just reactive or scheduled—but intelligent, dynamic, and future-ready.

Jai Balachandran is an industry expert with a proven track record in driving digital transformation and Industry 4.0 technologies. With a rich background in asset management, plant maintenance, connected systems, TPM and reliability initiatives, he brings unparalleled insight and delivery excellence to Plant Operations.