This Bearing Didn’t Fail Suddenly — The Vibration Data Was Screaming for Months

Industrial failures are rarely acts of fate. They are acts of omission.

Somewhere inside a plant, weeks or even months before a catastrophic breakdown, a bearing began to whisper. Its vibration signature shifted subtly. Frequencies nudged upward. Harmonics emerged. The machine was not silent—it was communicating. Yet no one truly listened, not because the data wasn’t available, but because the system wasn’t designed to turn insight into action.

This is not a story about a defective bearing.

It’s a story about how modern plants still fail in predictable ways—and how leaders can stop it.

The Myth of “Sudden Failure” in Industrial Maintenance

Overview: Why “sudden breakdowns” are almost never sudden

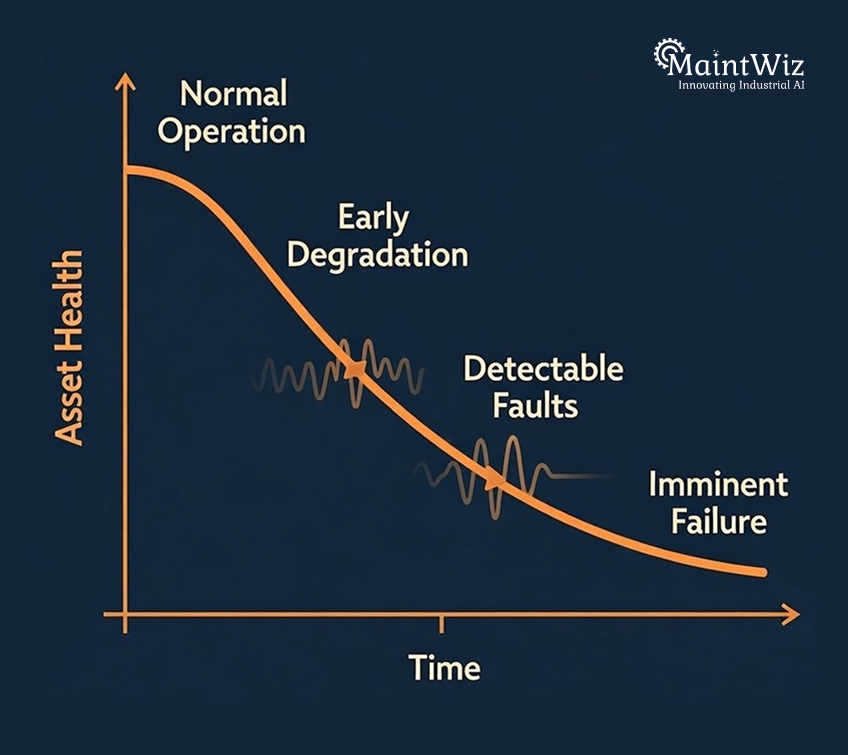

In decades of asset management and plant operations across manufacturing, energy, utilities, and process industries, one truth remains consistent: equipment failures follow patterns. Bearings, motors, gearboxes, and pumps degrade gradually, governed by physics, not randomness.

Yet post-failure reports still use the phrase “unexpected breakdown.” That phrase is comforting—but misleading.

Why failures are predictable, not random

- Mechanical degradation follows known curves

Fatigue, wear, lubrication loss, and misalignment all produce identifiable vibration patterns long before failure. - Early-stage faults are subtle, not dramatic

The most valuable signals are small deviations, not alarm-level spikes. - Machines don’t hide problems—organizations do

Data is generated continuously, but often trapped in disconnected tools. - Failure is usually a decision delay, not a detection failure

Signals are seen, but action is postponed due to workflow gaps.

The bearing didn’t fail suddenly. The organization failed slowly.

What the Vibration Data Was Actually Saying

Overview: Understanding how bearings “speak” through vibration

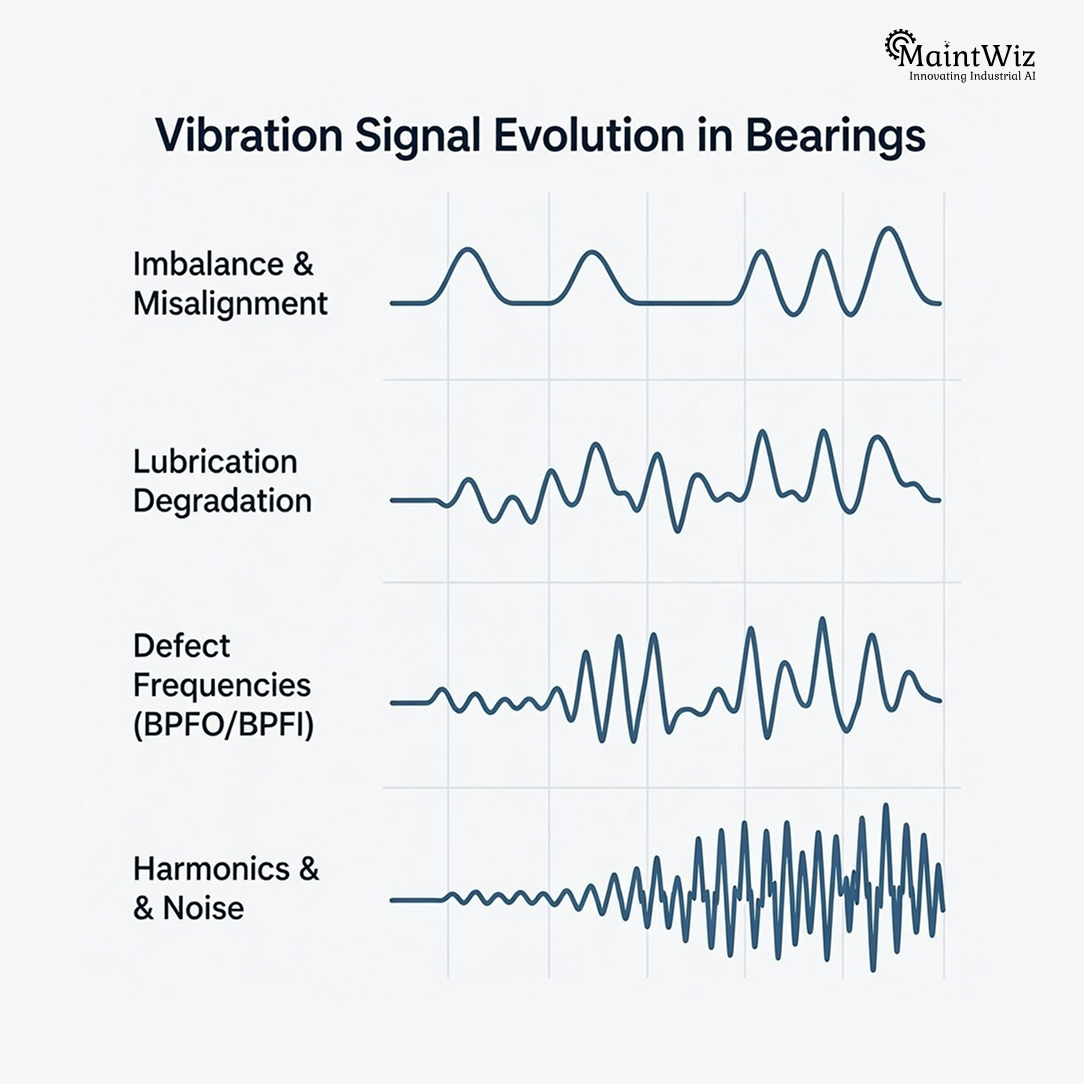

Vibration analysis is one of the most mature and powerful condition monitoring techniques in industrial maintenance. When interpreted correctly, it provides a timeline of degradation.

The typical vibration warning sequence before bearing failure

- Initial imbalance and misalignment indicators

Slight increases in overall vibration velocity signal early mechanical stress. - Lubrication degradation signatures

Changes in high-frequency acceleration often indicate lubrication breakdown. - Defect frequency emergence

Ball pass frequencies (BPFO, BPFI) appear as bearing surfaces deteriorate. - Harmonics and sidebands intensify

Faults grow more severe and predictable. - Noise overwhelms the signal—too late

By the time alarms spike, failure is imminent.

In most cases, this progression unfolds over weeks or months, not hours.

Why Plants Miss These Early Vibration Signals

Overview: The systemic blind spots in traditional maintenance models

If vibration analysis is so powerful, why do failures keep happening?

The answer lies not in technology gaps, but in organizational design and system architecture.

The most common reasons vibration warnings are ignored

- Condition monitoring is siloed from CMMS

Vibration data lives in specialist tools, disconnected from work execution. - Static alarm thresholds ignore asset context

One-size-fits-all limits miss asset-specific degradation trends. - Manual interpretation creates decision latency

Analysts review data periodically, not continuously. - Alerts don’t automatically create work orders

Insight without execution authority dies quietly. - Maintenance backlogs hide emerging risk

Early warnings compete with urgent breakdown tasks. - Leadership dashboards focus on lagging KPIs

MTTR and downtime are measured after damage is done.

This is not a failure of vibration technology—it’s a failure of integration.

The Execution Gap: When Data Exists but Action Doesn’t

Overview: Why insight without execution creates false confidence

Many plants believe they are “doing predictive maintenance” because they collect vibration data. But data collection is not prediction, and prediction without execution is just analysis theater.

How the execution gap forms

- Sensors detect anomalies

The data is technically correct. - Alerts are generated but not contextualized

Severity and business impact are unclear. - No automatic prioritization occurs

Alerts sit alongside hundreds of low-value tasks. - Work orders depend on human escalation

Delays become inevitable. - Failure occurs before intervention

The alert becomes a post-mortem artifact.

This is the moment where modern CMMS must evolve from record-keeping to decision orchestration.

From Preventive to Predictive to Prescriptive Maintenance

Overview: The maturity curve every plant must climb

Maintenance evolution follows a clear progression. Most organizations believe they are further along than they truly are.

The four stages of maintenance maturity

- Reactive Maintenance (Fix After Failure)

- High downtime

- Emergency work dominates

- Unpredictable costs

- Preventive Maintenance (Fix by Calendar)

- Time-based schedules

- Over-maintenance of healthy assets

- Under-maintenance of degrading assets

- Predictive Maintenance (Fix by Condition)

- Sensor-driven insights

- Requires analytics and interpretation

- Still manual execution

- Prescriptive Maintenance (Fix by Optimal Decision)

- AI predicts failure windows

- CMMS auto-prioritizes actions

- Decisions optimized for risk, cost, and uptime

The final leap—from predictive to prescriptive—is where most plants stall.

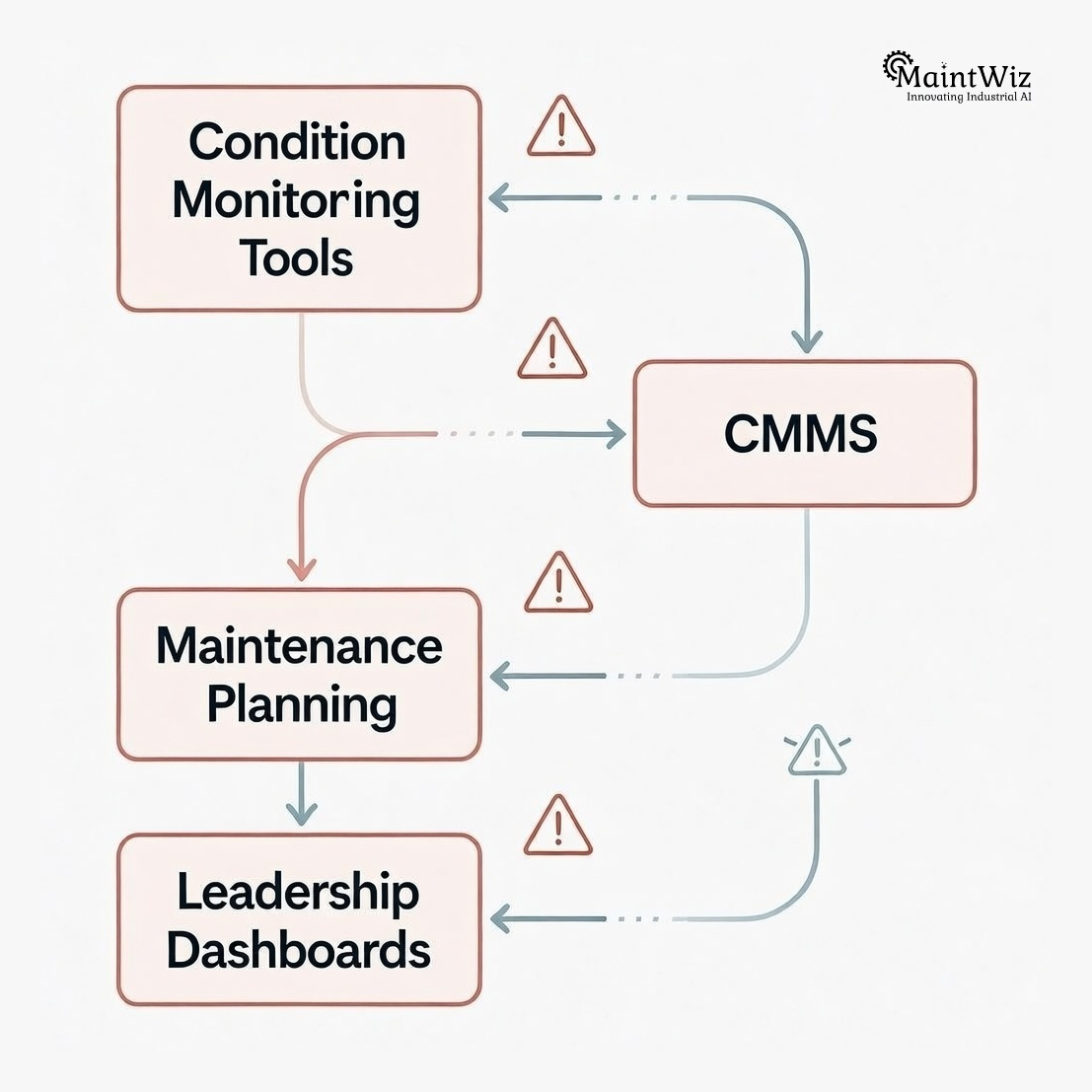

Why CMMS Is the Fulcrum of Reliability

Overview: Where insight becomes impact

Condition monitoring tools detect problems. CMMS determines whether those problems get fixed.

A traditional CMMS is passive. A modern CMMS must be intelligent, integrated, and proactive.

The new role of CMMS in modern plants

- Central nervous system for asset intelligence

- Bridge between condition data and execution

- Single source of truth for asset health history

- Decision engine for prioritization and scheduling

- Learning system that improves over time

Without this evolution, vibration data remains underutilized.

This is where platforms like MaintWiz CMMS fundamentally change the equation.

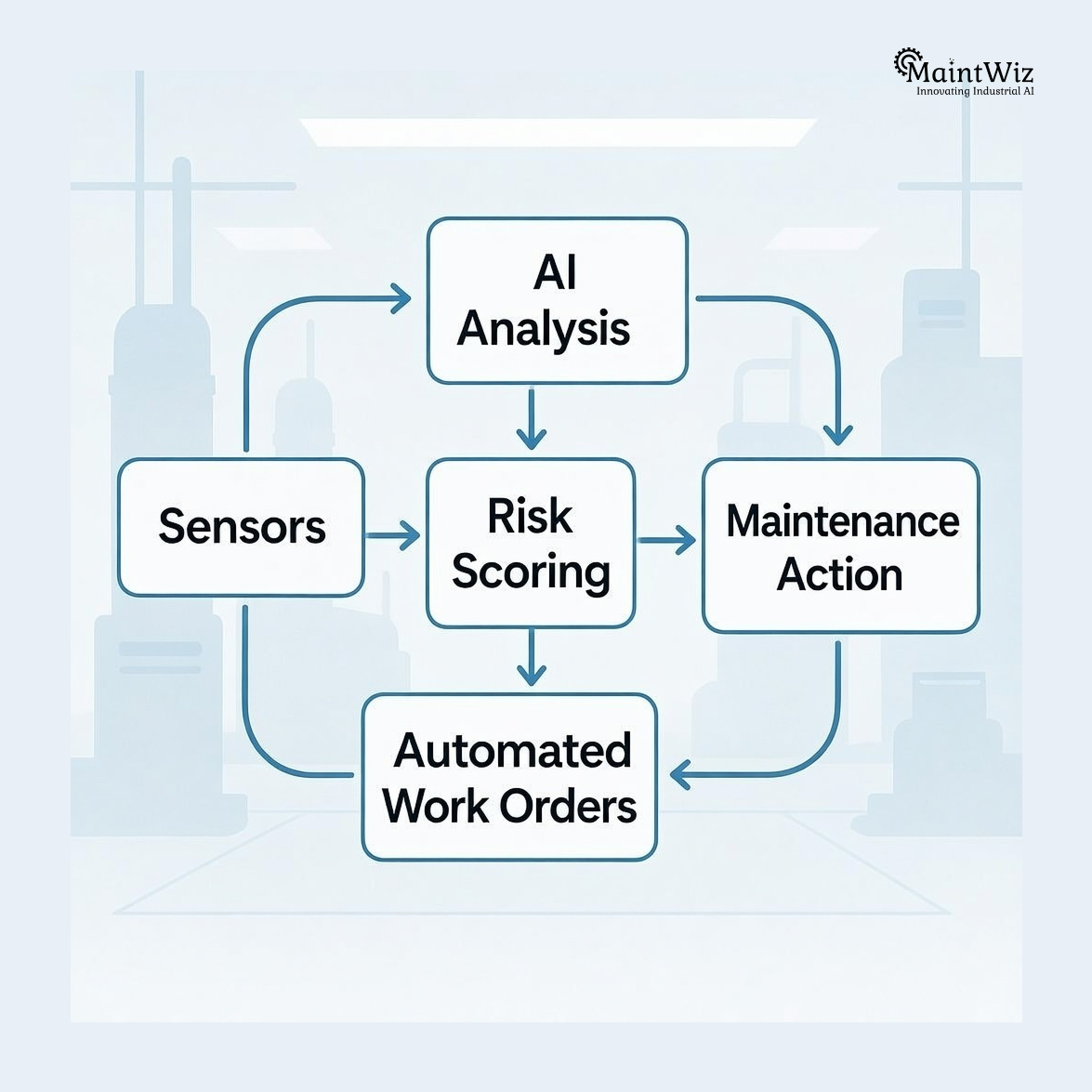

How AI Changes the Economics of Vibration Analysis

Overview: Moving from alerts to foresight

Artificial Intelligence does not replace vibration analysis—it amplifies it by removing human bottlenecks.

What AI-enabled vibration intelligence enables

- Continuous anomaly detection

Patterns are evaluated in real time, not during reviews. - Context-aware severity scoring

Alerts are ranked by asset criticality and failure impact. - Failure probability forecasting

Maintenance teams see when, not just what. - Automatic work order generation

No waiting for manual escalation. - Feedback-driven learning

Each maintenance action improves future predictions.

AI turns vibration data from a diagnostic tool into a strategic planning asset.

The Leadership Lens: Why This Is a CXO Issue

Overview: Reliability is no longer a shop-floor problem

Unplanned downtime is now one of the largest hidden drains on enterprise value. For asset-intensive industries, it directly impacts EBITDA, safety, customer trust, and capital efficiency.

Questions leaders should be asking

- Which assets are silently degrading right now?

- What failures are statistically inevitable next quarter?

- How fast do condition alerts become maintenance actions?

- Where is data disconnected from execution?

- What percentage of failures were preventable in hindsight?

If leadership cannot answer these questions confidently, the plant is operating on borrowed time.

Why MaintWiz CMMS Is Built for This Reality

Overview: From maintenance software to maintenance intelligence

MaintWiz CMMS is designed for the modern reality where condition data, AI, and execution must operate as one system.

It is not just a tool to log work—it is a platform to prevent failure by design.

How MaintWiz transforms vibration data into outcomes

- Integrated Condition Monitoring

MaintWiz connects vibration, temperature, and operational data directly to asset records, creating a unified view of asset health. - AI-Driven Predictive Maintenance

Advanced analytics identify early degradation patterns and forecast failure windows, not just threshold breaches. - Automated Work Order Orchestration

When vibration anomalies emerge, MaintWiz automatically creates and prioritizes work orders based on risk and impact. - Asset-Centric Intelligence

Each asset develops a living health profile, combining vibration trends, maintenance history, and performance metrics. - Lifecycle and Cost Optimization

MaintWiz supports data-driven repair vs replacement decisions, improving total cost of ownership. - Executive-Ready Dashboards

Leaders gain real-time visibility into asset risk, maintenance effectiveness, and reliability trends.

With MaintWiz, vibration data no longer “screams into the void.” It drives action.

Final Thought: Machines Whisper First

Machines don’t fail suddenly.

They whisper—through vibration, heat, and performance drift.

Whether those whispers turn into catastrophic screams depends on how intelligently an organization listens and responds.

In a world where downtime is optional and predictability is achievable, the difference is no longer technology—it’s system design and leadership intent.

MaintWiz CMMS exists for organizations ready to make that shift.

Jai Balachandran is an industry expert with a proven track record in driving digital transformation and Industry 4.0 technologies. With a rich background in asset management, plant maintenance, connected systems, TPM and reliability initiatives, he brings unparalleled insight and delivery excellence to Plant Operations.